Listing ID #4724977

Company Information

Ask for more detail from the seller

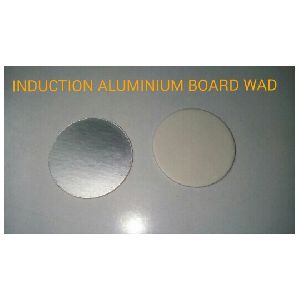

Contact SupplierInduction sealing wads are used to seal containers and protect their contents from deterioration or contamination due to access of air, moisture or any other undesirable impurity to the contents of the container. Induction sealing wads also prevent tampering or adulteration as it is not possible to remove and re-apply the wads without leaving noticeable evidence.

After the containers have been filled and capped, an induction current is created and passed through a conducting aluminium foil disc, present in the induction sealing wad, heating it up. The Aluminum disc has a layer of polymer film laminated to it, which melts, and sticks to the mouth of plastic or glass containers to give them airtight seal. The process takes a few seconds to complete and neither the container nor its contents have to cope with any temperature changes and remain unaffected. There are two types of Induction Sealing Wads :

Cap sealing wadsIn this type, the cap or closure for the container is separate from the induction sealing wad which is inserted into it. There are various kinds of wads and all are normally multi-layered. Broadly they can be categorized as :

Single Piece Sealing Wads are fitted into cap of the containers and screwed around the container mouth. These capped-containers are made to pass the induction heat sealer. With the threaded cap upon bottle providing required pressure, as sealing layer cools, it adheres to bottle and provides for a perfect sealed surface.

Two piece sealing wads normally consists of a uppermost layer of paperboard (that maybe glued to the cap). The next layer is wax that is used to bond a layer of aluminum foil to the paperboard. The lowermost layer is a polymer film laminated to the foil. After the cap or closure is screwed to the container , the container is passed under an induction coil, which emits an oscillating electromagnetic field. The induction coil begins to heat-up the conductive aluminum foil. The heat melts the wax, which gets absorbed into the paperboard layer and the foil is released from the cap. The polymer film also heats and flows onto the lip of the container. After cooling, the polymer creates a bond with the container resulting in an airtight sealed product. Two piece sealing wads are used for leaving some type of secondary seal in cap so as to prevent leakage when induction seal is removed from the mouth of the container.

Capless Sealing WadsCapless Sealing Wads are used when the container is not meant for reuse and the screwable cap is made redundant. The function of the cap seal is limited to providing an airtight and spill-proof seal to the contents of the container which are meant for single use only. The aluminum foil laminate is supplied either pre-cut in container neck shape or in reel form. Where it is supplied in a reel, it is die cut online and placed onto the container neck. It is then pressed down by the seal head, the induction cycle is activated and the seal is bonded to the container.

There are many benefits of Induction Sealing Wads :

Tamper evidence

The seal on the mouth of the container cannot be removed and reinstated without leaving evident sign of tampering. This also helps in differentiating real products from spurious similar looking products.

Leak prevention/protection

Installation of induction sealing wads is widely used in the food and beverage industry to prevent leakage and also to extend shelf life. It is sometimes mandatory to seal liquid chemical products before shipping to prevent them from spilling over other shipments.

Freshness

Induction sealing wads prevent contaminants present in the environment to mix with food products, and sometimes even increase the shelf life of products.

Pilferage protection

Induction sealing wads cannot be reinstated upon removal without leaving a trace of the original wad on the mouth of the container. This helps in identifying if any pilferage has happened. Infact, Pharma companies want to purchase wads that purposely leave film or foil remnants on containers as a deliberate safeguard against tampering or counterfeiting.

Sustainability

In some applications, introduction of induction sealing wads actually reduces the container weight as the presence of seal ensures enough security so as to prevent the need for a robust neck / closure.