Listing ID #4757062

Company Information

Ask for more detail from the seller

Contact Supplier| Description | ||

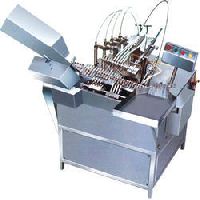

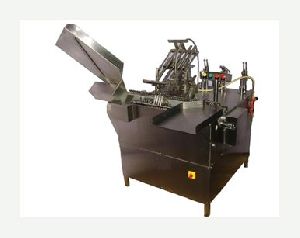

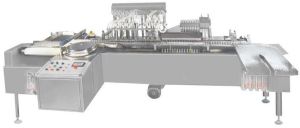

| High Speed Automatic Ampoule Filling & Sealing Machine is compact & versatile machine for the filling & sealing of glass ampoules. Our Automatic Eight Head Ampoule Filling & Sealing Machine provides output up to 12000 ampoules per hour and having usage in large batch production of injectables. Apart from the pharmaceuticals, this machine can also be useful for large scale production of cosmetics. Machine complies as per cGMP requirements and having crucial part of Injectable Ampoule Filling Line. | ||

| Salient Features | ||

| Compact cGMP model. | ||

| Self centering grippers for the transport of all ampoule diameters within the size range without the need to change. | ||

| Ampoule gas centering during gas flushing and filling. | ||

| Possibility of gas flushing before, during and after filling. | ||

| AISI 316L dosing syringes without gaskets. | ||

| Drip free adjustment for media of different viscosity. | ||

| “No ampoule No filling” function. | ||

| Full accessibility allows easy maintenance. | ||

| Fast change over due to extremely limited parts to be replaced. | ||

| Individual micro metric adjustment of syringes. | ||

| Dosing Syringes driven by separate brussless Motor. | ||

| Ampoule sampling unit without stopping the machine. | ||

| Possibility to memorize various parameters of different ampoule sizes. | ||

| Extremely robust, high engineered. | ||

| Higher out put up to 15000 Ampoules per hour. | ||

| Machine equipped with pre-warming station. | ||

| Flow Meters Makes Regulating Flames easier. | ||

| Minimum change over time, little maintenance, easy cleaning. | ||

| Critical Components made on CNC Machine. | ||

| Process Operation | ||

| Empty washed & sterilized ampoules fed into wire mesh conveyor belt from the left hand side of the machine. Eight ampoules fed through feeding cassette to receiving rack. The moving rack which moves horizontally collect eight ampoules from the receiving rack and transfer the ampoule to the machine in left to right in an inclined position through pre-gassing. Pre-gassing, Filling, Post Gassing, Pre-heating & sealing stations completes filling & sealing operations. Filled & sealed ampoules are collected automatically in SS tray in upright position without hand touch. | ||