Listing ID #3919059

Company Information

Ask for more detail from the seller

Contact Supplier|

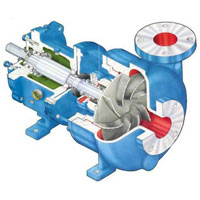

high pressure pumps are designed and manufactured by srs pumps with advanced pump technology which ensure quality, reliability and efficiency. Our high pressure pumps are horizontal, simplex or triplex positive displacement plunger pumps. our high pressure equipments is the most versatile, time-and-cost effective solution for cleaning, cutting, removing, descaling, testing, spraying etc. design: pump drive end assemblies are of rugged construction with high quality materials and heavy duty taper roller bearings. Bearings are lubricated by splash lubrication. Pumps are designed to permit rapid and economical maintenance, particularly regarding plunger, packing and valves are manufactured to ensure accurate alignment on reassembly. applications:

liquid ends: liquid ends can be offered in s.s 304, s.s.316,s.s. 316 l, hastelloy b or c, alloy 20, etc. technical specifications:

working principle: fluid can be accelerated to very high velocities through a nozzle by the application of sufficient hydraulic horsepower. Hydraulic horsepower is proportional to the product of fluid pressure and the volume delivered. Fluid velocity is proportional to the pressure developed through a nozzle orifice. The impact of high pressure fluid jets can remove deposits which defy mechanical cutting tools, without any damage to underlying materials by correct selection of nozzles, accessories and power sources. the high pressure unit consists of the following:

interchangeable conversion kits are available for all pump units so that the pressure/volume relationship can be altered to suit a particular operation without altering the pump speed, thus maintaining efficient working of the drive motors.

|