Listing ID #4203936

Company Information

Ask for more detail from the seller

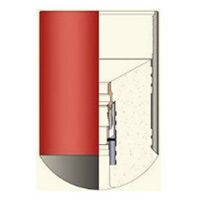

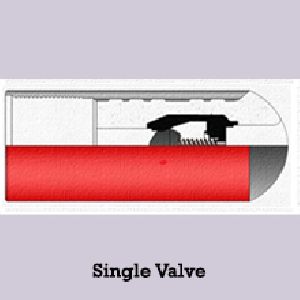

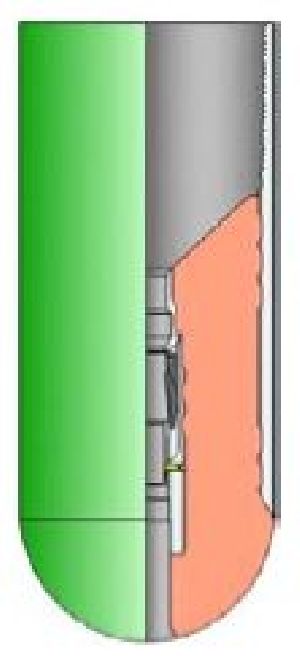

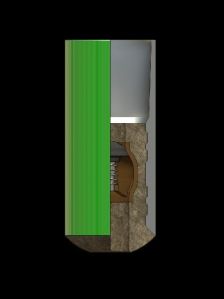

Contact SupplierStab-In cementing is an improved method for cementing large diameter casing. Conventional methods require excessive amounts of cement to ensure cement circulation to surface because of open hole volume, losses to the formation, or mud displacement efficiency that cannot be determined with sufficient accuracy. In addition, large plugs must be used to separate the cement from the mud and have to be drilled out, along with any cement in the casing. With stab-in cementing, the Drill Pipe is stabbed directly into the Float Shoe or Collar and cement is pumped through the drill pipe until returns reach surface. Cement is then displaced to the bottom of the Drill Pipe — a wiper dart can be used. The drill pipe is then picked up, circulated, and pulled out of the hole.

Use : The WELLCARE Stab In Float Equipments are used for cementing large diameter casings lowered on drill pipe. The string presents special cementing consideration due to high displacement volume of large diameter casing. Problem with high displacement are overcome by using Stab in Cementing Equipment to allow cementing through drill pipe.

Features :

Advantages :