Listing ID #3864564

Company Information

Ask for more detail from the seller

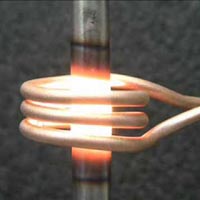

Contact SupplierCommitted to excellence-Increase performance-Drive Innovation-Act responsively -Value People-Attract and empower talent-Customer focused Non-siliconized or low-siliconized semi-finished strip is increasingly used for the manufacture of magnetic cores for electrical equipment. The cores are fabricated from cold rolled strip which undergoes critical deformation after recrystalization and must be annealed after punching. Following annealing, core loss is of an order of 2 to 4 W/kg for a sheet thickness of 0.5 to 0.7mm. Electrical sheet manufactured by this process is superior to dynamo strip not only with regard to cost but also with regard to:

Appropriate temperature and furnace atmosphere control induces three simultaneous heat-treatment effects needed to fabricate material of the properties required. The hard, fine-grained ferritic structure is transformed into a soft coarse-grained structure according to ASTM series 2½ to 3½. At the same time, the carbon content of the metal is reduced to less than 0.005% to prevent any effect of residual carbon on the properties of the material ageing. Further, an oxide coating is obtained at a temperature of 550°C. Decarburization and plating necessitate permanent contact between the reaction gas and the strip surface. The oil, normally applied prior to punching the laminations, is burnt off in the first heating zone.

| Coe Loss | Unit | After Punching | After Annealing |

|---|---|---|---|

| P1.0 | W/Kg | 8.0-9.5 | 2.9-3.2 |

| P1.5 | W/Kg | 16.5-18.5 | 5.5-7.5 |

| Flux Density | |||

| B 25 | T | 1.45-1.55 | 1.64-1.68 |

| B 50 | T | 1.68-1.70 | 1.74-1.77 |

| Aging | % | 0-2 | 2-3 |

| Carbon Content | % | 0.060-0.080 | 0.003-0.005 |

| Grain Size | ASTM | 8-10 | 2-3 |

| Oxide Layer Thickness | M | 0 | 0.8-1.6 |

| Burr Height | mm | Max 0.05 | Max 0.04 |

| Vickers Hardness HV 5/30 | Kp/mm2 | 130-160 | 60-80 |

| Tensile Strength | N/mm2 | 380-450 | 250-300 |

| Yield Strength | N/mm2 | 3330-360 | 200-250 |

| Elongation | 0% | 15-25 | 25-35 |