Listing ID #3877642

Company Information

Ask for more detail from the seller

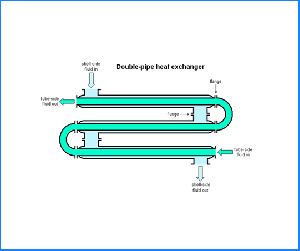

Contact SupplierBEV undertakes design, manufacture, testing, certification and code stamping of shell and tube heat exchangers, air cooled heat exchangers, air cooled condensers etc. to ASME Sec VIII Div 1, TEMA, API 660 / API 661. Also we design and manufacture plate fin heat exchangers such as steam coil air preheaters. Various applications include process gas coolers, lub oil coolers, HP / LP Heaters, Condensers etc. to customer specifications. BEV holds ASME ‘U’ and U2 Stamps and National Board ‘NB’ and ‘R’ Stamps. The plant is approved by Hartford Steam Boiler UK Ltd. (Notified Body) for manufacture of pressure vessels under Pressure Equipment Directive PED 2014/68/EU of the European Union, Module H1 and H. Heat exchangers for steam related application such as HP Heaters can be manufactured under IBR Stamp.

BEV has a team of competent design engineers, design associates and draftsmen experienced in the field. Thermal design of heat exchangers can be performed using either proprietary software like HTRI or custom developed spread sheets. Generally PV Elite supplemented with custom developed spread sheets is used for mechanical design and latest version of Autocad for drafting. Finite element analysis, stress analysis, vibration analysis etc. can also be carried out by our design associates.

Materials of construction range from carbon steel through stainless steel including exotic metals like SMO (6% Mo), Duplex/Super Duplex Stainless Steel, Hastelloy, Inconel, Incolloy, Titanium, Cu Ni etc. For material preparation, we have a CNC profile cutter with plasma and oxy fuel torches. We can roll shells up to 85 mm thick and 3.2 M wide. Cold working is maximized with CNC band saw, Universal Steel Worker etc.

We have a wide range of welding manipulators such as column and boom 4 M x 7 M, heavy duty rotators up to 50 tons and positioners up to 3 tons. We have the entire range of welding gear viz., SAW, SMAW, GTAW and FCAW welding machines. We also have BugO Speed Weaver welding oscillator for GTAW / FCAW and custom developed jigs for tube to tube sheet welding. There are also baking and holding ovens for welding electrodes and flux, apart from portable quivers for welders and welding operators. For stainless steel and exotics, there is a purpose built, segregated area.

We have a well equipped machine shop with a 3 Axis CNC Vertical Machining Centre Hartford PRO 3210 imported from Taiwan with bed size 3150 mm x 2100 mm with 70 bar through coolant BT50, 6000 rpm spindle, 20 tools ATC, right angle milling head and Fanuc controller. Tube sheets and baffle plates drilling, facing and gasket grooving can be accomplished with high precision and minimum turnaround time. We also undertake job work on tube sheets and baffle plates. The machine shop also has a radial drill and 3 gap bed centre lathes. Exotic metals are handled using stringent material control and handling procedures and work is carried out in controlled environment. We carry out post weld heat treatment / stress relieving in temporary purpose built temporary furnaces within our facility or in gas fired furnaces at a specialist subcontractor’s premises of pressure vessels. Semi automatic and manual FCAW is used for welding of saddles, supports and stiffeners.

Heat exchanger tubes, plain and finned, straight as well as U tubes are available from local suppliers. There are reputed manufacturers in our approved suppliers list, including some with R/D 1.0 bending capability. For tube expansion, we have state of the art digital wattage controller and sets of expanders and mandrels of various sizes. Tube end facing, beveling can be done using portable ID mounted machines.

Hydro testing up to 600 bar can be done with or without chart recorders. Pneumatic testing and / or helium leak testing could also be done.

For ASME Code Stamped jobs, we have an Authorised Inspection Services Agreement with Hartford Steam Boiler Inspection and Insurance Company of Connecticut. Hartford Steam Boiler International GmbH is the Notified Body for PED certification jobs. We also have a second AIA services agreement with Lloyds Insurance Inc. GOST-R certification for Russia or GOST-K certification for Kazakhstan can also be arranged through duly accredited certification bodies.

Country specific compliance certification such as that for Malaysia, Singapore, Australia etc. can also be arranged through authorized third party inspection agencies such as Bureau Veritas. This would facilitate seamless integration of our equipment into the project in the country of installation.

We have an extensive range of WPQRs to ASME Sec IX and EN ISO 15614 covering a wide range of materials, thicknesses, processes and other variables. All our WPQRs are witnessed and certified by third party inspection agencies such as Bureau Veritas, TUV Nord etc. Welders could also be qualified in presence of third party inspection agencies if it is a requirement. If Client requires us to appoint an independent third party inspection or certification agency, it could be arranged.

We have a totally enclosed steel grit blasting facility complying with Euro III norms imported from Hodge Clemco, UK. Its size is 16M (L) x 8 M (W) x 5 M (H). Items bigger than this are blasted under custom built canopies using 200 litres blast pots and copper slag as abrasive medium. Painting facility is fully equipped with air less spray painting machine as well as cup guns. Special erosion resistant internal coatings can be applied using Belzona or Ceramkote products. Non destructive testing such as radiography, ultrasound etc. and material testing at NABL accredited testing facility is available within reach.