Company Information

Ask for more detail from the seller

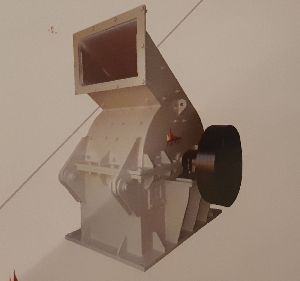

Contact SupplierWe are offering hammer crushing plant.

The material crushed by the hammer crusher through the collisions between high-speed hammer and materials. The hammer crusher were developed for both dry and wet crushing of brittle, medium-hard materials for the mining, cement, coal, metallurgic, construction material, road building, and petroleum & chemical industries.

Working principle:

the motor drives the rotor rotates of the hammer crusher at a high speed through the belt, and on the rotor there are series hammers. When the materials get into the working area of hammers, they are crushed by the rotating hammers of the hammer crusher with high rotation speed, the products which are crushed to meet the required size can be discharged by the outlet and become the final products, the large size products are brought back to the crushed area by the hammers of the hammer crusher for being re-crushed until they reached the required size.

Advantages:

high crushing ratio

high fineness of discharging size

simple operation process

low running cost

simple structure, high efficiency, light equipment quality and easy to operate and maintain

application:

hammer mills is used in areas of cement, construction material and mining industries for the materials with breaking strength no stronger than 200mpa. The size of feeding material is up to 450-1000mm and the average discharge size is ≤5-8mm, which is controlled effectively by multi-mode elastic adjusting mechanism.

Technical specification for hammer mill:

further reference to the above, below specification is for sample only.

Our product is customized one it will change as per customers requirement

make : star trace

equipment : hammer mill

size : 800 x 800

material in size : 60 mm

material out size : 22 mm

capacity : 10tph

shaft : en8 material

linear : harden square rod welded liner

hammers : harden hammers

chuke : inlet and outlet chuke provided

frame : ismc 100 m.s channel supporting structure provide

motor bed : motor bed integrated

starter : (optional)

motor power : 30 hp, 3phase, 415v, 50hz, 1440rpm

machine weight : 1500 (approx.)

scope of supply : hammer mill, motor, pulley, belt, mounting, frame, and bearing units.