Listing ID #3882064

Company Information

Ask for more detail from the seller

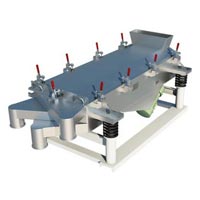

Contact SupplierGyro Vibratory Sieve separators are self-contained, compact, production machines which make precise mechanical separations according to particle size through efficient use of multiplane inertial vibrations techniques. These sieve separator are designed and built to solve the most difficult classifying, separating and dewatering problems.

Material to be screened is fed to the top screen. Oversize particles are moved by the multiplane motion to the screen periphery where it gets discharged. Undersize particle or liquid passes rapidly through the screen. Gyro Vibratory Sieve Separators are equipped to handle up to five screens.

The 3 dimensional inertial vibration of Gyro Vibratory Sieve Separator is based on a principle in which motor rotation imparts vibration to an entire screen assembly in both vertical and horizontal planes.

The top eccentric weight of the double extension shaft motor operates in a plane which is close to the center of the mass of the assembly. This generates a horizontal throw to the screen assembly. The bottom eccentric weight rotates below the center of mass, which creates a high frequency tilt on the screen.

The third dimension is a tangentile component produced by the combination of the horizontal and vertical movements. The tangential components moves oversize material laterally across the screen while encouraging undersize particles to flow through the screen.

Both top and bottom eccentric weights are independently variable of mass and angular relationship, giving a great degree of control over all vibration components. This results in the ability to obtain optimum conditions for screening nearly any material.

| Model | FGS-600 | FGS-750 | FGS-900 | FGS-1200 | FGS-1500 | FGS-1800 | FGS-2400 |

| Motor H.P. | 0.5 | 0.5 | 1.0 | 2.0 | 3.0 | 5.0 | 7.5 |

| DECK DIA. (in mm) | 600 | 750 | 900 | 1200 | 1500 | 1800 | 2400 |

| Capacity | Will depend upon screen size & feed material properties | ||||||