Listing ID #1488467

Company Information

Ask for more detail from the seller

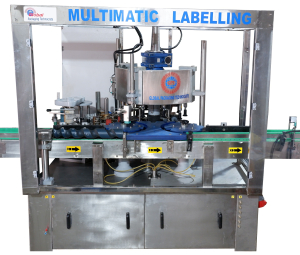

Contact SupplierWe hold expertise in manufacturing, exporting & supplying of Gum Labeling Machine from Gujarat, India. These machines efficiently perform the task of accurately and perfectly labeling bottles, plastics, etc. Moreover, our Gum Labeling Machine comes with the assurance of quality that won’t degrade over the course of time. We offer the machine at rational prices.

Description

Filsilpek solutions is automatically labels round container of glass, plastic, aluminum, pet, cardboard container, will wrap-around labels in the vertical position by using cold glue. JHL-150 is rigid, versatile and engineered for reliability and enhance operational efficiency in addition, it has several exclusive features, which offer additional advantages.

Operation :

The round containers positioned accurately by the feed worm for wrap-around operation at the operation at the labeling point, the rotating glue cylinder receives cold glue from gluepot that subsequently gets transferred on the Glue Rubber Roller. Finally a fine, even and thin film of glue is transferred to the gluing pad. The round container on the moving conveyor at the feed worm actuates a sequence, which result in the oscillation of the Label Box. The rotating Label Master aligned with the help of pick up fingers from the Label Master & with oscillating Label Box. The pick up cylinder receives labels with the help of pick up fingers from the label master. The pick up cylinder holds the labels perfectly with due to vacuum during its rotational movement. Simultaneously the pick-up fingers move inside. The round container moves on conveyor with the help of worm and glued label on pick-up cylinder wrapped around to container by virtue of strip belts. Then the labeled container moves further through a rubber pressing belt & stationary rubber pad that ensures neat & perfect fixing of label.

Salient Features :

|

Label Specification |

Length |

|

Width |

|

|

Thickness |

|

|

Container Size |

Round Shape |

|

Wet Glue |

Glass/Plastic/PET etc |

Details :

|

Electrical supply |

3 Phase + Neutral + Earthing |

|

Electrical load |

1 KW |