Listing ID #3831981

Company Information

Ask for more detail from the seller

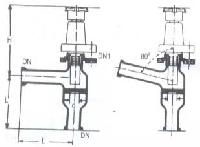

Contact SupplierThe globe valve is used for throttling flow control. Shut off is accomplished by moving the disc against the flow stream rather than across it as in the case with a gate valve. The globe valve is an excellent valve to use for on-off service, but is highly suited for frequent cycling and control of fluids anywhere in amount or volume between the open and closed positions.

OPERATING PRINCIPLES :-This is a valve which entails multiple turns during hand operation. It is basically a linear action valve that has a piston or disk which seats on a single shaped seat or flat.

They are mainly used to control the opening and closing of fluid flow.In the plumbing industry, globe valves are used to tightly seal when fully closed.This controls high pressure fluid streams in pipes. Fluid pressures vary from time to time while flowing. The valves have a stem that is vertically positioned in the body of fluid flow to control the changes in pressure. It has a globe-shaped body that is mainly separated by an inner baffle. It is the baffle which controls the flow and has two parts: ring shaped seat and the flat plug. we offer metal seatings so that the seating stress must not only high ,but also circumstantially uniform to achieve the desired degree of fluid tightness.

Cast Iron : IS 210 Gr FG 200

Cast Carbon Steel : ASTM A 216 Gr WCB

Cast Stainless Steel : ASTM A 351 Gr CF 8/CF 8M

Forged Carbon Steel : ASTM A 105

Forged Stainless Steel : ASTM A 182 Gr F304 / F316

End Connection : Screwed AS PER BSP/BSPT/NPT

Socketweld : AS PER ANSI B 16.11

Flanged : AS PER ANSI B 16.5

Pressure Rating : ASA 125#, 150#, 300#, 600#, 800#, PN 16 & PN 40

Engineering Option : Gear Operated, Electrical Actuated,

Size Range : 15mm to 300 mm

Valve Design : BS 5351 / ANSI B 16.34 / API 6D

Pressure Testing : BS 6755-I

Face To Face : ANSI B 16.10

Flange Drilling : ANSI B 16.5 / BS 10 Table / DIN / IS 6392

Butt Weld End : ANSI B 16.25

Socket Weld End : ANSI B 16.11

Screwed End : ANSI B 1.20.1(BSP/NPT)