Listing ID #5562814

Company Information

Ask for more detail from the seller

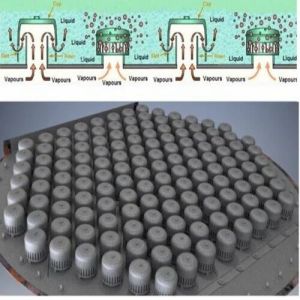

Contact SupplierThe combination of Glass Reactor with Rectification Column (borosilicate glass 3.3 distillation attachments) is an attractive approach that has been used effectively in the chemical and pharmaceutical industries.

In general, there is an important position in the manufacture of highly refined and highly pure products such as fine chemicals, plant protection agents, vitamins and pharmaceuticals, metal-free and highly corrosion-resistant material.

Best Manufacturer, Supplier & Exporter of Glass Reactor with Rectification Column, providing top notch after sales services to our clients with 100% satisfaction.

The working theory of the laboratory rectification tower: fluid mixing by partial gasification and condensation for several periods, as the various components have different instability characteristics, so that they can achieve the objective of mixture separation.

The rectifying glass reactor is famous for cleaning spices, intermediate pharmaceutical, new material, etc. For practice, the “reaction” and “distillation” processes are often sequentially performed to ensure that the initial materials react to the target products within the same equipment.

Key Features :

Types of Applications :

| Product Modle | AGRRC-10 | AGRRC-20 | AGRRC-30 | AGRRC-50 | AGRRC-80 | AGRRC-100 |

|---|---|---|---|---|---|---|

| Volume(L) | 10 | 20 | 30 | 50 | 80 | 100 |

| Neck No. on Cover | 6 | 6 | 6 | 6 | 6 | 6 |

| External Diameter of Inner Vessel(mm) | 230 | 290 | 330 | 365 | 410 | 460 |

| External Diameter of Outer Vessel(mm) | 290 | 330 | 365 | 410 | 460 | 500 |

| Cover Diameter(mm) | 265 | 265 | 265 | 265 | 340 | 340 |

| Vessel Height(mm) | 450 | 550 | 730 | 850 | 950 | 950 |

| Motor Power(W) | 140 | 140 | 140 | 140 | 250 | 250 |

| Vacuum Degree(Mpa) | 0.098 | 0.098 | 0.098 | 0.098 | 0.098 | 0.098 |

| Rotation Speed(rpm) | 50-600 | 50-600 | 50-600 | 50-600 | 50-600 | 50-600 |

| Torque(Nm) | 2.23 | 2.23 | 2.23 | 2.23 | 3.98 | 3.98 |

| Power(V) | 220 | 220 | 220 | 220 | 220 | 220 |

| Dimension(mm) | 650x650x1900 | 700x500x200 | 700x500x210 | 700x500x230 | 1000×700×250 | 100×700×2700 |

| Materials | 3.3High borosilicate glass,0.25L-200L is optional | |||||

| Receiving Flask | 3.3High borosilicate glass,1L-100L is optional | |||||

| Type of Stirring | different types of stirring paddles (anchor, paddle frame, impeller etc), which can be used for the stirring and mixing of different viscosity liquid. | |||||

| Condenser | 3.3High borosilicate glass,(0.3 ~3)square meters is optional | |||||

Ablaze Export Pvt. Ltd. is a well-known organization from Vadodara (Gujarat) that is instrumental in offering the finest range of industrials products. We serve as a dependable manufacturer, exporter and supplier of Distillation Units, Evaporators, Glass Reactors, Acid Concentration Plant, Dry HCL Gas Generator, Bromine Recovery Plant, Gas Absorber, Glass Pressure Relief Valve, Glass Coil Condenser, Mobile GAS Scrubber, Sulfuric Acid Dilution Plant, Easy Reactor Lifting System, Heating & Cooling Circulator, Glass Nutsche Filter, Glass Mixer Settler, and Glass Shell & Tube Heat Exchanger. We are also involved in handling turnkey projects for such offerings. These products are manufactured using the finest components and parts, which allow us in making available precision engineered products. Our distribution network is well-knit across all major global regions due to which we ship products safely and timely.

Ablaze Export Pvt. Ltd. is a prominent name in its area of operation. The company is based in Vadodara (Gujarat) and our Managing Director Mr. Rohit Gupta leads company’s business operations in the regional and international marketplaces. With years of industry knowledge and market exposure, he founded the company in the year 2010. We operate in the global market and serve the industrial demands with perfection and commitment.

Infrastructure

The company boasts of a sound infrastructural facility that is spread over sprawling area of land. Our facility comprises of modernistic equipment, design unit, and in-house quality testing facility, which help us ascertain products that conform to the highest standards of quality are shipped to buyer destinations.

Vendor Selection

We are a quality-conscious organization that selects vendors carefully in order to get the best quality materials for production. Following are the parameters on which we select our vendors: