Listing ID #4317187

Company Information

Ask for more detail from the seller

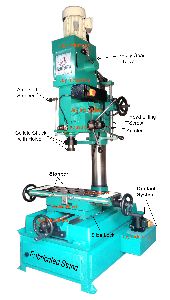

Contact Supplier| Model | LG - 250 | LG - 120 |

| Maximum Drilling Capacity (S45C) | Ø 25mm | Ø 16mm |

| Spindle Taper | MT3 | MT2 |

| Spindle Travel | 140mm | 80mm |

| Number Of Speeds | 6 | 4 |

| Spindle Speed | 250-2020 rpm | 470-1730 rpm |

| Throat (Column to Spindle Centre) | 230mm | 180mm |

| Column Diameter | Ø 102mm | Ø 80mm |

| Table Diameter | 420mm | 320mm |

| Base Size | 380 * 600mm | 300 * 500mm |

| Max Distance From Spindle To Table | 630mm | 400mm |

| Distance From Spindle To Base | 930mm | 600mm |

| Motor HP | 2HP | 1HP |

| Overall Height | 1600mm | 1050mm |

| Weight | 220kg | 100kg |