Listing ID #3831960

Company Information

Ask for more detail from the seller

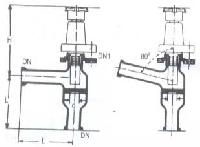

Contact SupplierA Stem [shaft] which moves perpendicular to the axis of flow of the working medium, there will be one gate or wedge in gate valve and it will control the fluid flow. Shape of gate or wedge of gate valve will be a type of flat circular plate or rectangular plate. Sometimes, gate or wedge is also termed as disc of gate valve.

Gate Valve handle wheel when rotated in clockwise direction, steam and gate will move in downward direction across the fluid flow line and gate will be tightly located between the two seats. Hence there will not be any leakage of fluid through the valve once valve is closed completely. When handle wheel will be rotated in anti-clockwise direction, steam and gate will move in upward direction across the fluid flow line and valve will be opened from closed position and will permit the flow of fluid through the gate valve. Once gate valve is completely opened, it will permit no resistance or very little resistance to the flow of fluid.

JD CONTROLS GATE VALVES:-

JD. Controls Gate Valves are Outside Screw, Rising Stem, Bolted Bonnet Construction, threads are away from the line fluid and easy to lubricate.

The body bonnet joint for all class of Gate Valve is in CircularRound/Rectangular Shape. In Gate Valve from 150# Rating body & bonnet joint have male-female type joint with a gasket. The Gate valve is also available in different types of Disc-Gate such as Double Disc Gate, Solid Gate, Flexible Gate, Parallel Slide Gate, Conduit Gate etc. to suit industrial various applications.

Rising Spindle: -Outside Screw & Yoke (OS & Y) design keeps the stem threads outside the valve and is recommended where high temperatures, Corrosives, and solids in the line might damage the stem threads inside the valve. When Gate Valve will open, the stem extends above the hand wheel indicates the position of the gate.

Valves Trims: –Trim refer to internal working parts of valves. In Gate Valves the Stem (Spindle), Seat Ring, Back Seat Bush, Gland Bush ARS trim parts.

Valves Seat: – It can be Integral Seat with body Casting.

Renewable: – Separate Seat Rings that screw into the valve body, which is called as Renewable Seats.JD Gate Valves are OS & Y Type, Rising Spindle, Bolted Bonnet design, threads are away from the line fluid and easy to lubricate. Gate Valve body ports are streamlined, permitting unobstructed flow, reduces turbulence, results in lower pressure drop and lower erosion. JD Gate Valves bonnet castings are of one – piece construction, where the yoke is integral with bonnet up to 6” size.

Our manufacturing range also covers JACKETED GATE VALVE, Thermic Fluid Hot Oil Jacketed Gate Valve & Steam Jacketed Valve for sticky, viscous, molten sulphur, bitumen, asphalt application.

JD An ISO 9001, ISO 14001 & OHSAS 18001 certified company Gate Valve Manufacturer, Alloy 20, Duplex Steel, Hastelloy, API 600, API6D, API 603 Standard Gate Valve Exporter, Supplier, Stockist, Importer. Rising Stem, Bolted Bonnet, Austenitic Stainless Steel Gate Valves, Flanged – Butt Weld End.

SALIENT FEATURES:Material of Construction:

Cast Iron : IS 210 Gr FG 200

Cast Carbon Steel : ASTM A 216 Gr WCB

Cast Stainless Steel : ASTM A 351 Gr CF 8/CF 8M

Forged Carbon Steel : ASTM A 105

Forged Stainless Steel : ASTM A 182 Gr F304 / F316

End Connection : Screwed AS PER BSP/BSPT/NPT

Socketweld : AS PER ANSI B 16.11

Flanged : AS PER ANSI B 16.5

Pressure Rating : ASA 125#, 150#, 300#, 600#, 800#

Engineering Option : Gear Operated, Electrical Actuated,

Size Range : 15 mm to 300 mm

Valve Design : API 600 / API 602 / API 603 / IS 780 / BS 14846

Pressure Testing : API 598

Face To Face : ANSI B 16.10

Flange Drilling : ANSI B 16.5 / BS 10 Table / DIN / IS 6392

Butt Weld End : ANSI B 16.25

Socket Weld End : ANSI B 16.11

Screwed End : ANSI B 1.20.1(BSP/NPT)

Applications:-