Company Information

Ask for more detail from the seller

Contact Supplierthe smelting unit is designed to recover the lead by processing lead bearing material from spent lead acid batteries. to recover the lead from lead bearing materials, it is necessary to carry out the chemical reactions at rotary furnace in presence of reagents at high temperature to remove the oxygen and sulphur elements from lead oxide and sulphate from lead bearing material. this is basically reduction process

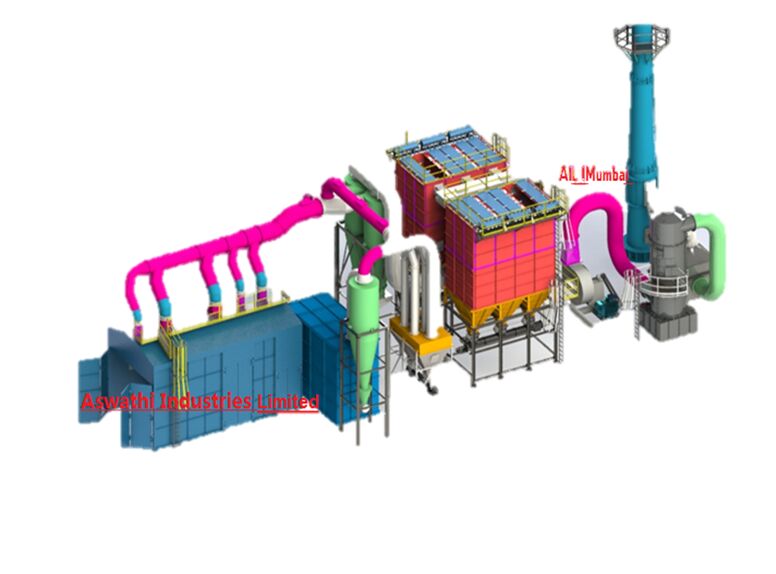

the most important aspect of lead smelting operation is treatment/conditioning of flue gases generated during chemical reaction takes place at rotary furnace. apc devices consists of settling chamber cum spark arrester, cyclone, heat exchanger (cooling tower), and bag house assembly, wet-scrubber, mist eliminator, induced draft fan and chimney with interconnecting ducting. hygiene/fugitive emission control – we have provided the total enclosure to furnace with hoods at charging/tapping/exhaust point of furnace to ensure no gases/fumes are escaped into atmosphere from smelting process. control dampers are provided at both the ducts connecting from hood to header to adjust the suction condition.