Listing ID #3929308

Company Information

Ask for more detail from the seller

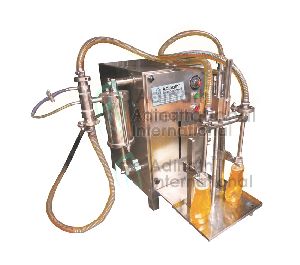

Contact SupplierThe filling heads offer a wide range of fill volumes and can handle low to high viscosity liquids. The nozzles are adjustable to fill foaming and non-foaming products with variable speed filling capacity. The honed 316L stainless steel filling pumps are available in 100 or 2000ml capacities and can be specified in single or double acting format. Optional touch-screen programming and the ability to store multiple filling profiles has greatly increased the efficiencies on line throughputs. Easy recall of container fill profiles has helped to de-skill the operating of this range

Features:

Options: