Listing ID #3870291

Company Information

Ask for more detail from the seller

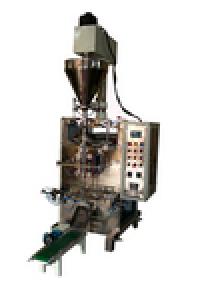

Contact SupplierWe are among the renowned names of the business, engaged in offering Fully Automatic Auger Filler Machine. Proffered packaging machine intakes plastic film, converts it into the form of pouch, accepts the material from dispensing system and then seals the pouches, by the help of pneumatically operated heaters.

In auger filler machine, the material to be filled is stored in the hopper. The stirrer of the machine facilitates the prevention of any bridging of the material. The Servo motor drive of the machine provides the perfection of accuracy and speed of the machine.

This machine is suitable for packing of :

Features:

Virtually maintenance free 24X7 operation

Micro controller based User friendly HMI.

In house Developed Electric Hardware.

Feeding mechanism through Servo motor, which enables high speed along with excellent accuracy.

Eye mark controller for perfect positioning of seal & cut

Provision for batch printing system (to be selected by you)

No film -machine stop mechanism (optional)

No material – machine stop mechanism (optional)

Easy change of roll system –(optional)

No’s of pouches produced – count batch wise/day wise.

Horizontal sealer with servo motor drive available as an option

Collar type forming system for elegant pouches

Leak proof sealed pouches assured through special vertical sealing method

Fiber optic sensor for level control of auger hopper

Level Controller for screw conveyor

Film pulling through durable long life timing belt instead of rollers

Electronic controls provided for minimizing power consumption (Optional)

Strip cut / single cut system provided

Benefits:

Flexibility and ease of operation

Excellent screw design ensures repetitive and within range “Count” and hence weighment.

No skilled operator required

Man power saving.