Listing ID #3819596

Company Information

Ask for more detail from the seller

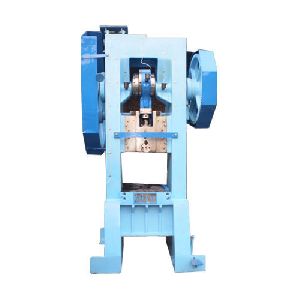

Contact SupplierThis Screw Press is also known as Forging Presses or Screw Presses. These Friction Screw presses are preferred for hot forming (Forgings) and cold coining, Stamping, embossing, Sizing nonferrous metals.

Features

| FSP | FSP | FSP | FSP | FSP | FSP | FSP | FSP | FSP | FSP | FSP | ||

| Nominal Capacity | Tons | 30 | 50 | 100 | 150 | 200 | 300 | 400 | 500 | 630 | 800 | 1000 |

| Dia of Screw | mm/inch | 75/3 | 115/4¼ | 132/5¼ | 155/6¼ | 165/6½ | 200/8 | 225/9½ | 255/10 | 280/11 | 292/11½ | 307/12½ |

| Stroke of Ram | mm/inch | 150/6 | 175/7 | 250/10 | 275/11 | 300/12� | 350/14 | 375/15 | 405/16 | 432/17 | 457/18 | 507/20 |

| Number of strokes | Per mintue | 40 | 30 | 25 | 20 | 18 | 16 | 14 | 12 | 10 | 8 | 6 |

| Size of Table | mm/inch | 325×350/13×14 | 325×400/13×16½ | 430×470/17×18½ | 450×525/18×21 | 500×540/20×21½ | 600×600/24×24 | 700×700/28×28 | 760×760/30×30 | 810×810/32×32 | 865×865/34×34 | 915×915/36×36 |

| Max.Distance B/W Table & Ram |

mm/inch | 300/12 | 325/13 | 450/18 | 475/19 | 500/20 | 580/23 | 600/24 | 625/25 | 660/26 | 710/28 | 760/30 |

| Min.Distance B/W Table & Ram |

mm/inch | 175/7 | 175/7 | 200/8 | 225/9 | 250/10 | 280/11 | 300/12 | 325/13 | 355/14 | 380/15 | 405/16 |

| Dia of Hole in the table |

mm/inch | 75/3 | 80/3¼ | 100/4 | 118/4½ | 125/5 | 140/5½ | 150/6 | 150/6 | 150/6 | 165/6½ | 190/7½ |

| Dia of Hole in the Ram | mm/inch | 38/1½ | 38/1½ | 50/2 | 64/2½ | 64/2½ | 64/2½ | 89/3½ | 118/4½ | 118/4½ | 125/5 | 125/5 |

| Pulley Size | mm/inch | 100/4B | 100/4B | 100/4B | 125/5C | 125/5C | 175/7C | 175/7C | 175/7C | 175/7C | 175/7C | 175/7C |

| Power Required | H.P./R.P.M | 3/1440 | 5/1440 | 10/1440 | 15/1440 | 20/960 | 25/960 | 30/960 | 40/960 |