Listing ID #4913139

Company Information

Ask for more detail from the seller

Contact SupplierIn a conventional Friction Screw Press, energy is transmitted from the transmission wheels to the flywheel by friction through a leather band. On the return stroke, energy stored in the moving parts is dissipated as heat by applying brake.

In our machines, the two transmission wheels on the conventional Friction Screw Press are dispensed with. The flywheel is driven by an AC servo/ spindle motor through a timer belt/ gear. The motor can be made to run the flywheel at a preset speed very precisely till the dies come very close. The motor is now disabled and the entire energy in the moving masses gets transferred to the job. When the moving die comes to rest, the motor is reversed and the ram returns to its home position very precisely. Since there is no mechanical braking, no energy is wasted during return stroke. The motor brakes on line – regeneration principle where the kinetic energy in the moving mass is converted to electrical energy and sent back to the mains. Since the drive motor does not run when the ram is stationary no energy is consumed during idling of press.

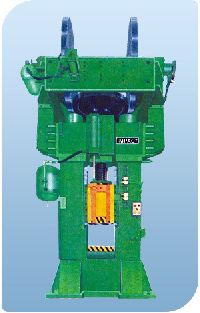

This press is used for making forged parts like Engine valve head. It consists of a vertical rectangular frame on top of which a servo controlled motor is mounted, which drives a Screw mounted with a fly wheel to move the ram of the press up and down. The ram bottom is fitted with top die, while the bottom die is mounted on the bolster plate of the press. The servo motor is made to run the flywheel at a preset speed very precisely till the dies come very close. The motor is now disabled and the entire energy in moving mass gets transferred to the job kept in the bottom die. When the moving die comes to rest, the motor is reversed and the ram returns to its home position. Since there is no mechanical braking, no energy is wasted during return stroke. The motor brakes by online-generation principle, where the kinetic energy in the moving mass is converted to electrical energy and sends back to the mains. Since the drive motor does not run when the ram is stationary, no energy is consumed during idling of Press.