Listing ID #3465320

Company Information

Ask for more detail from the seller

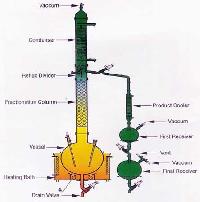

Contact SupplierThis unit is typically used for only distillation and fractionation under vacuum or at atmospheric pressure. The typical unit has distillation vessel fitted with a metal heating / cooling bath and with a packed column above reflux divider and coil condensers below are fitted on the packed column. Condensed material is either taken back to the vessel or to the receiver via product cooler.

The above units are available in 10 Ltr., 20 Ltr., 50 Ltr.,100 Ltr., & 200 Ltr.

Optional Items

| Reactor Capacity | Bath KW | Addition Vessel | Vapour Line | Condenser HTA M2 |

Cooler HTA M2 |

Receiver Size | Reference |

|---|---|---|---|---|---|---|---|

| 10 L | 2 | 2 L | 50 DN | 0.2 | 0.1 | 2L, 2L | SFFDU 10 |

| 20 L | 3 | 2 L | 80 DN | 0.35 | 0.1 | 2L, 5L | SFFDU20 |

| 50 L | 4.5 | 5 L | 100 DN | 0.5 | 0.2 | 5L, 10L | SFFDU 50 |

| 100 L | 6 | 10 L | 150 DN | 1.5 | 0.35 | 10L, 20L | SFFDU 100 |

| 200 L | 9 | 20 L | 150 DN | 1.5 | 0.35 | 10L, 20L | SFFDU 200 |

| 300 L | 10.5 | 20 L | 225 DN | 2.5 | 0.5 | 20L, 20L | SFFDU 300 |