Listing ID #3921795

Company Information

Ask for more detail from the seller

Contact SupplierDescription

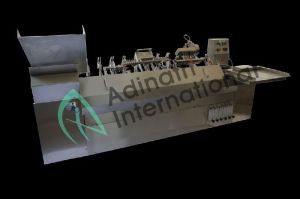

Harsiddh Engineering offers the best quality four head closed ampoule filling and sealing machine that works on ampoule’s incline drive principle in which closed mouth ampoules open up, filling and sealing takes place to care of wide aberration. Heavy plated machine covered with SS cover and matt/dull finishing. There is a big gap at the bottom of the machine for easy cleaning. The electrical control panel is placed on the top of the machine for easy start up, execution and protection. Our ampoule filling and sealing machines have CE certifications.

It is new generation machinery that opens, fills and seals the ampoules with nitrogen pre and post flushing with easy adoptability to the rectangular feeding that avoids the ampoule breakage. The instrument defined for complex process with easy execution to fill and seal 1ml to 10ml ampoules with closed mouth. It is highly efficient to handle 60 to 90 D type glass ampoules per minute. Though the output productivity is based on the sizes of ampoules, equipped with four sealing nozzle for pre-heating. Thick glass ampoules needs pre heating requisite for sealing. The greatest benefit of Ampoule Filling And Sealing Machine is less change over time, the parts made of quality Stainless steel.

This one is the most suitable device to fill and pack pre-washed or pre-sterilized closed ampoules probably used in foreign countries, where it requires high sterile and hygienic standards to be followed in vaccines and human consumption liquids are used to pack.

Silent Features