Listing ID #4171282

Company Information

Ask for more detail from the seller

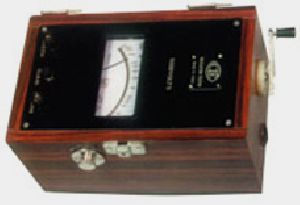

Contact SupplierThe Four Ball Tester is an excellent development and quality check instrument for developers and users of lubricants and additives. The unique sample configuration of three bottom balls and one top ball makes a very stable and a repeatable contact in-turn, allowing tests results to be very repeatable.

The Four Ball Tester can be used to determine Wear Preventive properties (WP), Extreme Pressure properties (EP) and friction behavior of lubricants. The wide acceptance of test results of the Four Ball Tester make it an excellent choice to benchmark products. It is a good choice for R&D due to its relatively inexpensive samples and ability to produce quick and repeatable results.

A rotating steel ball is pressed against three steel balls firmly held together and immersed in lubricant under test. The test load, duration, temperature and rotational speed are set in accordance with standard test schedule. In Wear Preventive (WP) tests – also called Anti Wear (AW) tests – the average scar diameter on the bottom three balls is reported. The size of the scar shows the ability of the lubricant to prevent wear. A larger diameter indicates poor wear preventive property while a smaller indicates superior wear preventive property.

In Extreme Pressure (EP) tests the lubricant is subjected to load that is increased in specified steps after every run. This increase in loading is continued till a load is reached where the lubricant fails. The failure of lubricant is indicated by welding of the bottom three balls to the top ball. The load at which welding occurs is the index of extreme pressure property of the lubricant.