Company Information

Ask for more detail from the seller

Contact SupplierApplication :

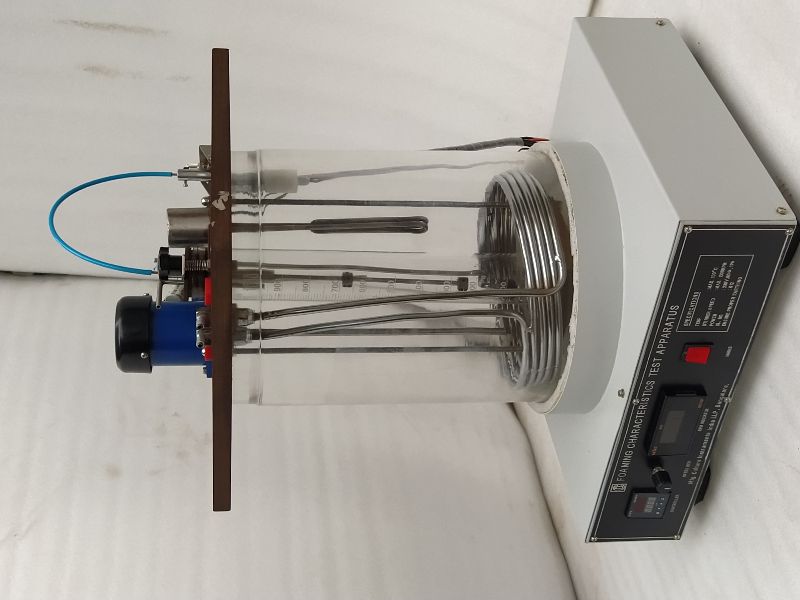

To determine the Foaming of lubricating oils in applications involving turbulence, high speed gearing or high volume pumping, which can cause inadequate lubrication, cavitation, overflow and premature oxidation.

Instrument Description and Construction Consists of two constant temperature baths with1000mL test cylinders,(certified) diffusers, air delivery tubes, and flow meters.Supplied with uP based temperature controls, S.S .immersion heaters and circulation stirrers to maintain temperature uniformity.

Dual LED displays process and set point temperature values. Test cylinders are held in place by SS weights. 24°C bath has coils for circulating exit air from the 94ºC and a separate coil for circulating cooling water.

All controls are enclosed in a sturdy bottom frame made of C.R sheet with elegant powder coated finish.

Standard Accessories/parts

11032-00 Base frame with controllers - 1 set 11032-01 Glass Test Baths - 2 nos. 11032-02 Bakelite Top Lids with circulation coils, Stirrer and heaters - 2 set 11032-03 Diffuser stone with tube and Rubber cork - 2 set xxxx-xx Air Compressor - 1 nos. xxxx-xx Silicone Tube - 2 Meter 11032-04 Measuring Cylinders - 2 nos. 11032=05 SS Sinker Weights - 2 nos. 11032-06 Glass/Acrylic Flowmeters - 2 nos.

Optional Accessories

11032-04 Measuring Cylinder 1000ml 11032-07 Certified Gas Diffuser 11032-06 Glass/Acrylic Flowmeters 11032-01 Glass Test Bath 11032-08 Spare High temp. bath heater 11032-09 Spare low temp. bath heater 11032-10 Spare Stirrer Motor 11032-11 Spare Moisture Trap xxxx-xx Wet gas flow meter xxxx-xx Cryostat for low temp. bath coolingxx