Company Information

Ask for more detail from the seller

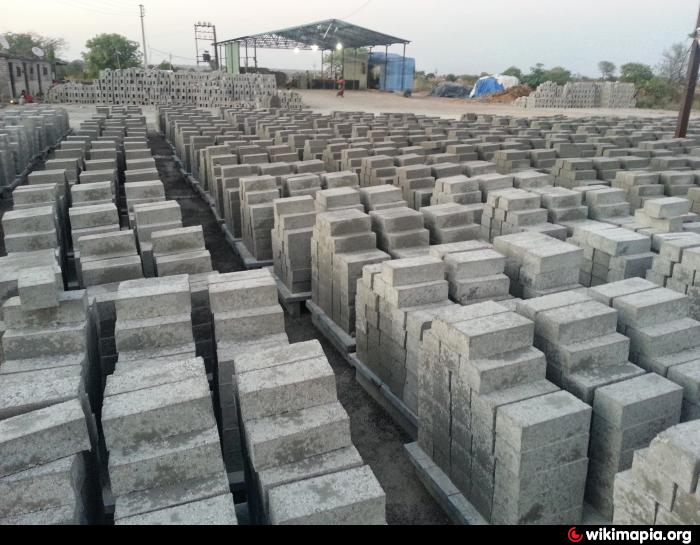

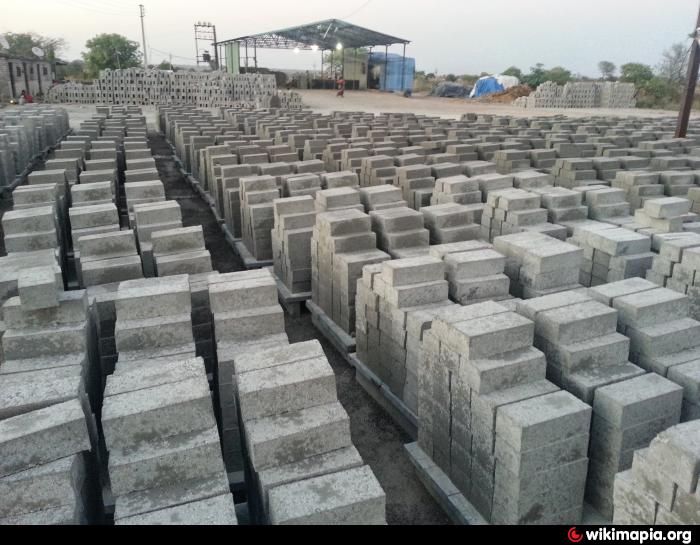

Contact SupplierFly ash brick (FAB) is a building material, specifically masonry units, containing class C ily ash and water. Compressed at 28 MPa (272 atm) and cured for 24 hours in a 66 oC steam bath, then toughened with an air entrainment agent, the bricks last for more than 100 freeze-thaw cycles. Owing to the high concentration of calcium oxide in class C fly ash, the brick is described as "self-cementing". The manufacturing method saves energy, reduces mercury pollution, and costs 20% less than traditional clay brick manufacturing. Sangopang bricks are eco friendly, not creating any environmental hazards. lt has long term strength, high workability, and better durability. It has high uniformity in shape and size could be supplied in every season.

Items | Usual clay burnt bricks | Sangopang Fly Ash Bricks | |

|---|---|---|---|

Dimension in mm (LxBxH) | 250mmx125mmx75mm | 190mmx90mmx90mm | 230mmx110mmx70mm |

Density (gm/cc | 1.60-1.70 | 1.80-1.90 | 1.80-1.90 |

Dry weight in kgs | 3.75-4.00 | 2.80-2.90 | 3.3-3.5 |

Common building bricks compressive strength (kg/cm2) | 50-65 | 70-90 | 130-150 |

Water absorption (in%) | 15-25 | 10-15 | 10-15 |

Thermal conductivity | Average | Good | Good |

Breakage | 5-71/21percent | <1% | <1% |

Eco-friendly | No | Yes | Yes |

Mortar saving: During Laying During Plastering |

N.A N.A |

10-15% 25-30% |

10-15% 25-30% |

Labour Cost | 20-30% | 15-20% | 15-20% |

Quality Control | Less possible | 100% | 100.00% |

Qutside plastering | Must | May be avoided | May be avoided |

Water treatment | Labour cost involved | Not at all required | Not at all required |

Dipping in water before use prior brick work Cost Effective | (24 hrs must.) No (High Cost) | Saves labour cost Yes (Less cost) | Saves labour cost Yes (Less cost) |