Listing ID #3941137

Company Information

Ask for more detail from the seller

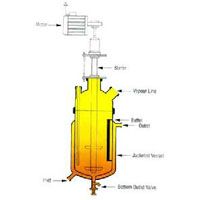

Contact SupplierThe FBR process is the latest advance in attached growth aerobic biological treatment technology. FBR employs RING PAC MEDIA, neutrally buoyant bio film carrier elements, to achieve outstanding BOD/COD removal productivity from a compact bioreactor. In Fluidized Bed Reactors, the liquid to be treated is pumped through a bed of small media at a sufficient velocity to cause fluidization. In the fluidized state the media provide a large specific surface for attached biological growth and allow biomass concentrations in the range 10-40 kg/m3 to develop.

For aerobic treatment processes the reactor is aerated. This is done by recalculating the liquid from the reactor to an oxygenator where air, or possibly oxygen, is bubbled. To overcome problems related to high re-circulation rates, needed when there is high oxygen demand in the reactor, the reactor might be aerated directly. The basis for the use of fluidized bed systems is the immobilization of bacteria on solid surfaces. Many species of bacteria (and also other microorganisms) have the ability for adhering to supporting matrices. In this process, a volume of Ring Pac media is immersed in water and is fluidized (kept in constant motion) through the movement of gas and liquid in the treatment reactor. As the media supports a biomass concentration several times that achievable in activated sludge systems, treatment is significantly more productive.