Listing ID #4805361

Company Information

Ask for more detail from the seller

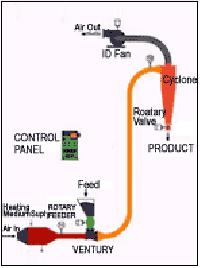

Contact SupplierFLUID BED DRYER MACHINE:

Fluid bed dryer machines and equipment specially designed Liquid Bed Processing includes quick drying, cooling and agglomeration of particulate materials. It is perfect for warmth delicate and non heat touchy items in Pharmaceuticals, Chemicals and Biochemical, Food and Dairy Industries.

The Fluid Bed Dryer have a bed of strong particles which are fluidized by passing a surge of air upward through an extraordinarily structured punctured sheet. The upward speed of air is so kept up in order to somewhat lift the strong particles and get them under way. This movement can be used to achieve blending just as forward development of the solids particles. The air is warmed and the procedure tourist evaporates the liquid and dries the solids. Fines get agglomerated to bigger granules particles in this way giving vast size

The machine is structured with right volume of bowl, air speed, heading and the temperature of the spotless delta air is kept up all through the fluidization, hindering, and development chambers, filtration region, pitch of the punctures of the plate at the base of item holder, the watertight fluidization space by appropriate fixing, material of the channels and procedure controls with electrical and pneumatically.

The uniform drying is accomplished by uncovering the full surface of each molecule of the strong mass to the approaching high speed tourist.

Choice for the procedure parameters are constrained by utilizing most recent PLC controls with HMI contact screen along these lines making gear operationally sheltered and killing the likelihood of human blunder. The procedure consistency with group records is kept up for each clump without fail.

The gear can be inbuilt CIP framework gives an altogether cleaned hardware for each cluster disposing of tainting of ensuing groups.

STRIKING FEATURES :|

Container Volume Liter |

Batch Capacity Kg. |

Drying Temp. °C |

Blower Motor hp/kw |

Heating loads Kw |

Steam consumption kg/hr |

|

| Bhagwati - 30 | 100 | 30 | Atm. to 85 | |||

| Bhagwati -60 | 220 | 60 | Atm. to 85 | |||

| Bhagwati - 120 | 410 | 120 | Atm. to 85 | |||

| Bhagwati -200 | 590 | 200 | Atm. to 85 | Please contact us for more details. | ||

| Bhagwati -250 | 750 | 250 | Atm. to 85 | |||

| Bhagwati -300 | 950 | 300 | Atm. to 85 | |||

| Bhagwati -500 | 1500 | 500 | Atm. to 85 | |||