Listing ID #3906473

Company Information

Ask for more detail from the seller

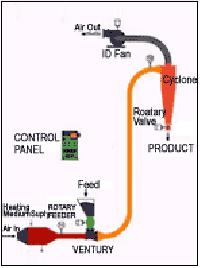

Contact SupplierThe operation of the fluid bed dryer is very simple whereby the drying of the material takes place by forced air circulation inside the chamber.

The atmospheric air is drawn through the air micron filter by a specially designed blower mounted on the top of the dryer. The clean air then passes through the heating elements (electric cheater / steam / thermic fluid radiator) to reach the required temperature. The hot air then passes through the product container and the product gets dries faster by air fludization. The air circulation is controlled by means of dampers. A Filter bag provided inside the drying chamber prevents the finest of particles of the material from entering the air stream. The main chamber is provided with on explosion flap to protect against pressure buildup inside the chamber. Digital temperature controller for the inlet air and temperature indicator for the outlet air comes as a standard.

Higher capacity models are provided with automatic operation like automatic bag shaker timer, pneumatic damper (butterfly valve) operation, process timer, sampling valve with bottle, etc is provided as a standard. Fully automatic operation with data logging through a PLC is provided as an option.

For higher capacity models, the blower can be detached for mounting in the service area to reduce noise level and isolate maintenance from the production area.

Granulation Line:- Fluid Bed Dryer Manufacturer In India with a highly versatile machine for drying of granules, crystalline & coarse powders and similar materials for the pharmaceutical, chemical, food, dyestuff and allied industries.