Listing ID #3812139

Company Information

Ask for more detail from the seller

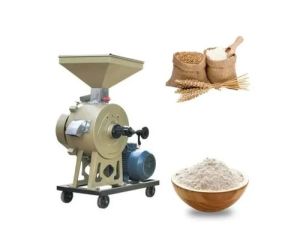

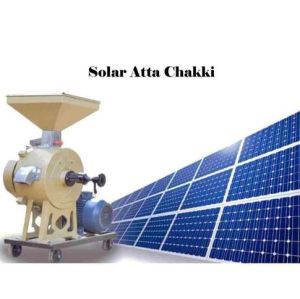

Contact SupplierThe traditional Stone Ground method grinding of wheat between stones is used to develop a flour of the highest quality. It is slow process that helps to retain the flours natural state of minerals, vitamins and proteins.

The stone ground flour motto of, “nothing added nothing removed” means exactly that. The goodness that goes in the top of the mill is what comes out at the bottom. The Stone Mills flour is stone ground in a very special way. This stone grinding process ensures a particularly natural and healthy end product. No iron or preservatives or any other colours or bleaching agents have been added. The stone mill is one of the original mills used for grinding wheat, uses a combination of compression, shear, and abrasion. The grinding action occurs between two stones. The material is fed into the centre of the top stone, which is fixed and does not rotate. The bottom stone is driven by a drive mechanism. The grinding gap between the stones is adjusted with a hand adjustment that raises and lowers the stone. The raw wheat material is then ground between the stationary and moving stone and the material is pushed radically to the circumference by grooves and furrows cut into the face of the stone. The ground material is discharged by the rotation motion and is conveyed out by the furrows.

Chakki milling in India is almost same as Stone milling in the western world. The basic principal of Stone milling is same as the Household Chakki milling. There are enhancements like automatic control of the spindles to adjust space between the disks. The process results in 15% to 20% starch damage and no loss of Ash.

| ITEM NO. | F951 | F751 | F851 |

|

|

|

|