Listing ID #4001161

Company Information

Ask for more detail from the seller

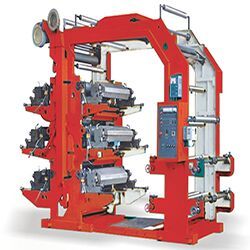

Contact SupplierBy perfectly integrating the new generation of electronics and ergonomically designed mechanical components, the machine is made to deliver optimum performance and productivity.

MSC's range of converting equipments is designed and developed to achieve high standards in flexible packaging. Its state-of-the-art technology offers excellence in converting solutions.

Companies specializing in flexo printing wanted a press that is perfect in design, could accommodate a wide variety of printing jobs and provide an impressive return on investment. They also required that a press should be possible to customize for their own needs. We delivered. The MSC-FL is a combination of intelligent design and intelligent economics.

Distinctively designed strong and sturdy, heavy-duty steel frame structure, completely machined on CNC-VMC, maintains accuracy over long dependable life and ensures less vibration even with optimum line speed.

The mechanical construction of each component, which undergoes extensive tests, ensures optimum performance and longer equipment life. Completely re-designed precision bearings and locking mechanisms provide anti-vibration guarantees

Hydraulic make web guiding system for unwind station. Air Shaft on unwind and rewind both station.

Master operator control panel and remote operator control panel consists touch screen operating interface facilitates ease in operation.

Safety of operator, machine and electronic modules are achieved with the help of necessary hardware protection and intelligent software routines.

Direct web tension control by using three drive control system consists of Load cell based closed loop vector controlled individual AC frequency drives for (I) Unwind station (II) Main drive (III) Rewind station.

Auto web tension control system by using vector controlled SIEMENS based AC drive & motor

Vector controlled SIEMENS based AC drive & motor.

Auto web tension control system by using vector controlled SIEMENS based AC drive & motor.

Hydraulic throw-off system for plate cylinder with separate hydraulic motor ensures continuous rotation of anilox roller which will not allow ink dry-up during machine stop operation.

Specially designed, dynamically balanced low friction-low inertia idle rollers made of Aluminum alloy, mounted on low friction bearings, enhance rotational smoothness.

Speed variable, air motorized Ink pump on each station with ink flow/pressure adjusting valve. (Optional)

The system mainly composed of matt chromium plated steel roller, and rubber covered nip roller with pneumatically adjustable pressure.

Drying Chamber: Mainly consists of AC frequency drive controlled heavy-duty blower with connection duct and dampers to balance fresh and recycling air.

The optimized air flow, minimizes heat consumption and avoid solvent retention in the printed substrates.

Central Exhaust System: AC frequency drive controlled solvent extraction system to exhaust contaminated air from all the print stations through central duct

Ceramic Anilox Rollers

Robotic plasma coated and laser engraved with improved cell structure ceramic anilox rollers with quick change over mounting arrangement..

Chamber Doctor BladeSpecially designed chamber doctor blade group, ensure straight profile of the blade resulting in lesser chamber pressure, better print quality & longer anilox roll life

Motorized Web Video Inspection SystemMotorized web video inspection system consists of high quality CCD color camera, Industrial PC & Monitor (facilitates sequential inspection of the lateral and entire print repeat of the web).

- Perfect Registartion.

- Uniform Impression.

- Double Winding & Unwinding Stand.

- Tension Control System.

- Web Aligner

- Doctor Blade System