Company Information

Ask for more detail from the seller

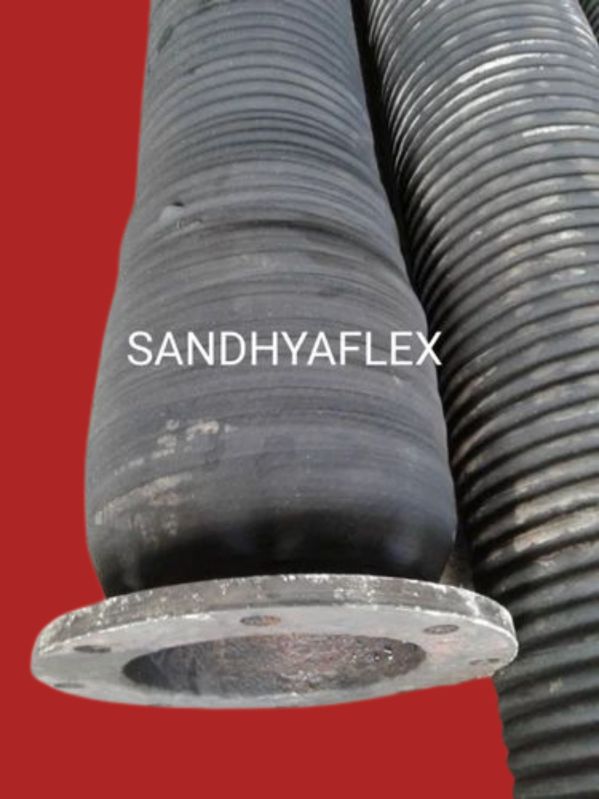

Contact SupplierA flexible rubber hose with a flange is a type of rubber hose that features flanged ends or connectors. These flanges are designed to facilitate secure and leak-proof connections between the hose and other equipment or piping components, such as pumps, valves, tanks, or other hoses. Flexible rubber hoses with flanges are commonly used in various industrial applications where the transfer of fluids, gases, or materials requires a reliable and sealed connection.

Here are some key features and considerations related to flexible rubber hoses with flanges:

**Key Features:**

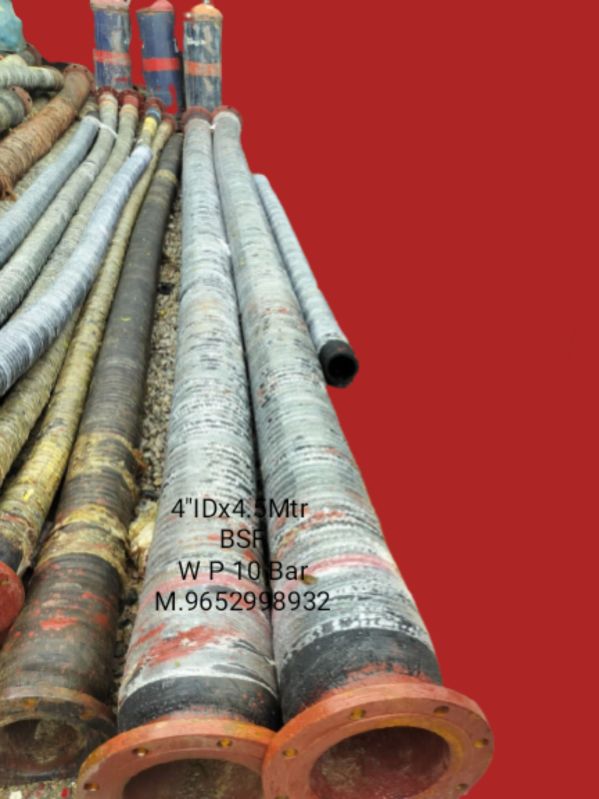

1. **Material:** The hose itself is typically made from high-quality rubber or synthetic rubber compounds that offer flexibility, durability, and resistance to abrasion, chemicals, and weathering. The choice of rubber material may depend on the specific application and the fluid or material being transferred.

2. **Reinforcement:** These hoses are often reinforced with layers of high-strength materials, such as textile fabric, steel wire, or synthetic fibers. The reinforcement provides structural integrity and prevents hose collapse or bursting under pressure.

3. **Flange Ends:** Flexible rubber hoses with flanges have flanged connectors at each end. These flanges are usually made of metal, such as carbon steel or stainless steel, and are designed to match industry-standard flange dimensions.

4. **Flange Types:** There are different types of flanges, including slip-on flanges, weld-neck flanges, and others, each with its specific use and connection method. The choice of flange type depends on the application.

5. **Size and Pressure Rating:** These hoses come in various sizes and pressure ratings to accommodate different flow rates, fluid pressures, and connection requirements.

6. **Flexibility:** Flexible rubber hoses are designed to be flexible and adaptable, allowing for movement and positioning within the system. This flexibility helps prevent kinking or twisting during operation.

**Applications:**

Flexible rubber hoses with flanges find applications in a wide range of industries and settings, including:

1. **Chemical Processing:** They are used in chemical plants to transfer various chemicals, acids, and corrosive fluids between different parts of the processing system.

2. **Petroleum and Oil Industries:** These hoses are employed in the transportation of crude oil, refined petroleum products, and other hydrocarbons in refineries, tank farms, and distribution facilities.

3. **Water and Wastewater Treatment:** They can be used in water treatment plants and wastewater facilities to transfer water, sludge, and chemicals.

4. **Maritime and Offshore:** Flexible rubber hoses with flanges are used in ship and offshore platform systems for the transfer of various liquids, including seawater, oil, and fuels.

5. **Industrial Manufacturing:** They find applications in various industrial processes, including food and beverage manufacturing, pharmaceuticals, and power generation.

6. **Construction and Mining:** These hoses are used for dewatering, slurry transfer, and other fluid-handling tasks in construction sites and mining operations.

Proper selection, installation, and maintenance of flexible rubber hoses with flanges are essential for ensuring their integrity and safe operation. Inspection and replacement of hoses that show signs of wear, damage, or deterioration are crucial for preventing leaks or disruptions in fluid transfer processes. Additionally, adherence to industry standards and safety guidelines is essential when using these hoses in industrial applications.