Listing ID #3944269

Company Information

Ask for more detail from the seller

Contact SupplierSide Bar Filter Presses

Our range of supply for side bar filter presses comprises:

Small & Medium size filter presses

for plate sizes: € 500 mm and € 1000 mm, upto 16 bar operating pressure.

The hydraulic closing device can either be chosen as manual or electro-hydraulic unit.

Filter presses for automated operation

Plate sizes: € 800 mm up to € 1500 mm, operating pressures ranging from 5 to 16 bar. For this filter press system two well-proven skeleton versions are available:

Skeleton made from cast iron:

This version is especially recommended for severe operating conditions in chemical and metallurgical industry.

Skeleton made from steel:

This type has been developed especially for operating pressures >16 bar.

Of course it is possible to have product-wetted parts of both filter press types equipped with corrosion-resistant coatings.

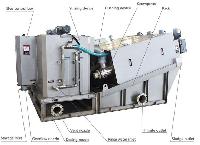

The basic components of a filter press are:

Closing of Filter Plate Set. Automatic hydraulic with maintaining pressure device.

Hydraulic Cylinder

Double Acting chrome-plated.Pressure-upto 325 kg/Cm2 Stroke- 150 to 1000 mm and on request upto 3000 mm Capacity- 30 Tons to 300 Tons

Power Pack-

Power Pack consists of high-pressure radial plunger Pump. Hand operated Directional Control valve, Solenoid valve, pilot operated check valve, Relief valve, Oil Filter, pressure gauge, Electric Motor. Working Pressure: upto 325 kg/Cm2

Design for Flame- Proof & Non-flame proof area.

Filter Plate Set

Chamber plates in standard design are fabricated of pressure-resistant and corrosion-proof polymer. Other materials such as cast iron, ductile iron, aluminum, stainless steel available on request. Filtrate discharge is available either in open design through spigots into a filtrate trough or in closed design through corner ports into discharge pipes.

Filter Cloths

Push-through filter cloths made of polyamide, polypropylene, polyester, cotton or other materials.

Special Equipments Control Panel.

Equipped with operating components, control and motor centers, mounted on the filter press, ready for connection.