Listing ID #3875563

Company Information

Ask for more detail from the seller

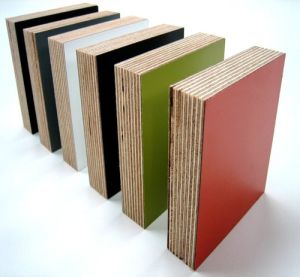

Contact SupplierMayur Film Coated Plywood is perfect for easy smoothening of concrete surface. For enhanced durability, the edges of the waterproof coating on these plywoods are sealed with water resistant paint. This makes it a perfect choice for RCC construction, as it withstands not just water but also abrasive action of concrete and vibrations caused by heavy equipment. It is overlaid with phenolic resin impregnated film and has high reusability, and also enables cost savings of up to 49% when using in construction.

Features