Listing ID #3811274

Company Information

Ask for more detail from the seller

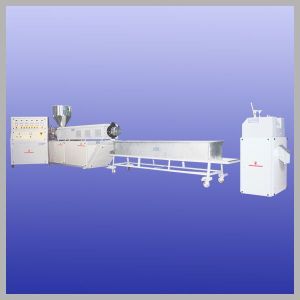

Contact SupplierHot feed screw type extruders are heavy-duty machines built to suit individual needs. They are made in many different type and sizes to meet the production requirements for straining extruding, tubing, slab production or contoured shapes. The extruder’s size depends upon the hourly output required and method of feeding with a complete line of equipment is available to meet with all customers need.

The Cold feed Extruders have been developed for processing cold rubber compound. Since these machines in addition to extruding profiles also plasticize rubber; they differ from hot feed extruders, they have longer screws; heavier gears boxes and higher drive power. According to present stage of development cold feed extruders can be used for extruding almost all rubber compounds, which are process able on hot feed extruders. Feeding is normally in the form of strips or pellets. Machines with longer screw diameters are often fed directly with wig-wag stored slabs.

Home

| About Us | Our Products | Download Catalog | Contact Us | Enquiry |

| Rollers for Printing Industry Read More | Rollers for Paper Industry Read More | Rollers for Steel Industry Read More | Turnkey Projects Read More | Machinery Read More | Compounds Read More |

| Exhibitions Read More | Rollers for Allied Industry Read More | New Entry Read More | Press Room Chemicals Read More |

Home » Our Products » Machinery » Extruder Machine

|

Extruder Machine

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||