Listing ID #1827257

Company Information

Ask for more detail from the seller

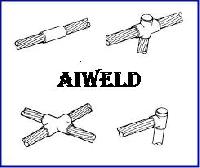

Contact SupplierExothermic Welding powder is also known asexothermic bonding, thermite welding (TW), and Thermit welding. There are many advantages of using Exothermic Welding powder. The most important one being that the process produces a molecular joint and not just a mechanical one in between the conductors. It is produced through a starting reactant which provides enough energy to activate the welding reaction. This takes place quickly and safely inside a graphite mould. The mould is designed specifically for a certain union depending on the elements to be welded and the joint type required. We guarantees all types of joints, not only copper cable unions but also to weld tapes, brass metallic pieces, stainless steel, steel ground rods covered with copper, etc. It is especially useful for joining dissimilar metals.

FEATURES OF EXOTHERMIC WELDING:

Exothermic Welding:

Exothermic Welding is a welding process for joining two electrical conductors that employs superheated copper alloy to permanently join the conductors. The process employs an exothermic reaction of a copper thermite composition to heat the copper, and requires no external source of heat or current. The chemical reaction that produces the heat is an alumina thermic reaction between aluminium powder and a metal oxide.

The reaction reaches very high temperatures, depending on the metal oxide used. The reactants are usually supplied in the form of powders, with the reaction triggered using a spark from a flint lighter. The activation energy for this reaction is very high however, and initiation requires either the use of a "booster" material such as powdered magnesium metal or a very hot flame source. The aluminium oxide slag that it produces is discarded.

When welding copper conductors, the process employs a semi-permanent graphite crucible mould, in which the molten copper, produced by the reaction, flows through the mould and over and around the conductors to be welded, forming an electrically conductive weld between them. When the copper cools, the mould is either broken off or left in place. Alternatively, hand-held graphite crucibles can be used. The advantages of these crucibles include portability, lower cost (because they can be reused), and flexibility, especially in field applications.

The weld formed has higher mechanical strength than other forms of weld, and excellent corrosion resistance. It is also highly stable when subject to repeated short-circuit pulses, and does not suffer from increased electrical resistance over the lifetime of the installation. However, the process is costly relative to other welding processes, requires a supply of replaceable moulds, suffers from a lack of repeatability, and can be impeded by wet conditions or bad weather (when performed outdoors).

Overview:

In Exothermic Welding powder, aluminium dust reduces the oxide of another metal, most commonly iron oxide, because aluminium is highly reactive. Iron(III) oxide is commonly used:

Fe2O3 + 2 Al → 2 Fe + Al2O3

The products are aluminium oxide, free elemental iron, and a large amount of heat. The reactants are commonly powdered and mixed with a binder to keep the material solid and prevent separation. Commonly the reacting composition is 5 parts iron oxide red (rust) powder and 3 parts aluminium powder by weight, ignited at high temperatures. A strongly exothermic (heat-generating) reaction occurs that via reduction and oxidation produces a white hot mass of molten iron and a slag of refractory aluminium oxide. The molten iron is the actual welding material; the aluminium oxide is much less dense than the liquid iron and so floats to the top of the reaction, so the set-up for welding must take into account that the actual molten metal is at the bottom of the crucible and covered by floating slag.

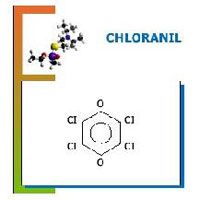

Other metal oxides can be used, such as chromium oxide, to generate the given metal in its elemental form. Copper thermite, using copper oxide, is used for creating electric joints in a process called Cad welding:

3 CuO + 2 Al → 3 Cu + Al2O3

TOOLS REQUIRED FOR EXOTHERMIC WELDING PROCESS

1) Graphite Mould

2) Mould Handle Clamp (Universal)

3) Steel Metal Disk

4) Exothermic Weld Powder

5) Ignite Powder (Starting Powder)

6) Gloves

7) Flint Gun

8) Brush (Soft and Hard)

9) Slag Removal Tool

10) File Card

11) Sealing Compound