Company Information

Ask for more detail from the seller

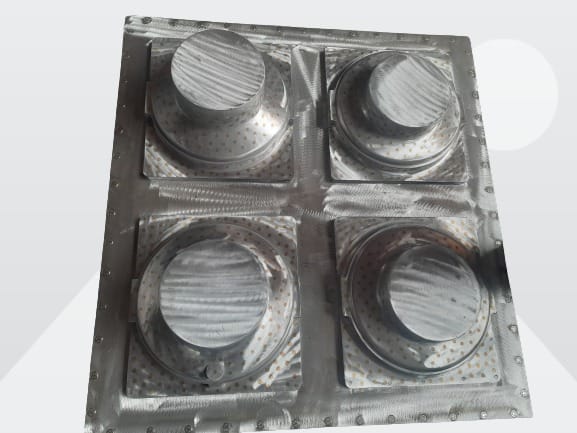

Contact SupplierJ P Machine Tools having all in house facilities to make EPS mould, like aluminum casting on electric furnace and using best grade aluminum alloy to process casting work (Lm-6, 6063 and Hindalco made 99.7 pure aluminum alloy), Design and Development. We make mould in supervision of qualified engineers and skilled person. We do all machining work on VMC to take accuracy and finishing.

We offer EPS mould with perfect shape of packaging and better strength using high quality raw material

We follow below steps to make mould.