Company Information

Ask for more detail from the seller

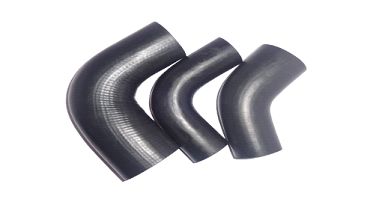

Contact SupplierEPDM stands for Ethylene Propylene Diene Monomer, a synthetic rubber used in a range of applications. EPDM is used most commonly used in the automotive and construction industries for various seals due to its excellent resistance to environmental factors such as Ozone, UV and general weathering. Typical applications of EPDM are window and door seals (glazing), waterproofing sheets and electrical gaskets.

EPDM Application

EPDM Benefits and Advantages

EPDM Moulding Processes

Sizes