Company Information

Ask for more detail from the seller

Contact Supplier

forehearth colouring technology is the introduction, melting and dispersion of colorants in the forehearth channel instead of the glass tank. it allows one or more forming machines to produce individual colors without a full tank changeover. it creates a flexible color operation without sacrificing the economies of large scale tank production.

with forehearth colouring technology there is no need to color the entire tank. it is perfect for short-run color campaigns. can switch colors more easily than in the tank and it is very cheaper to switch dark colors back to flint. it allows cost-effective colored glass to be made near to the market. it fits with current moves to rationalize and reduce the number of glass plants and tanks.

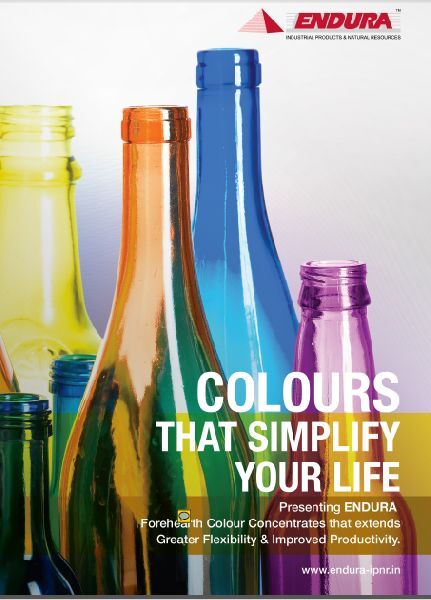

markets & applications: cosmetic bottles, beverage bottles

developed by intensive in-house research & development. is used for bulk production in pioneer glassware industries. it has no dust generation due to spherical shape (2-6mm). consistency & uniformity in every batch. application and after sales support. higher colour intensity & particle size distribution. increased productivity due to low dosing rate and least dust generation. stability over wide range of temperature