Listing ID #2226412

Company Information

Ask for more detail from the seller

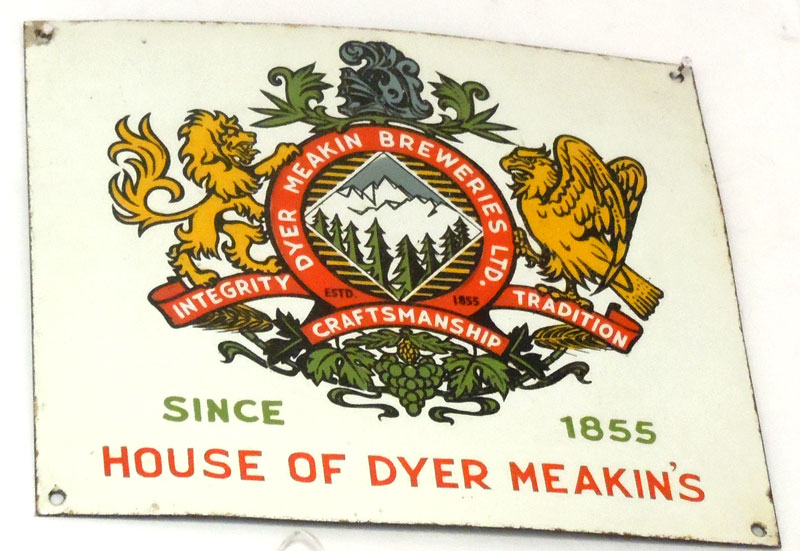

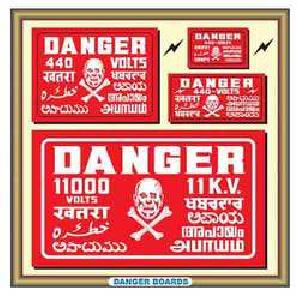

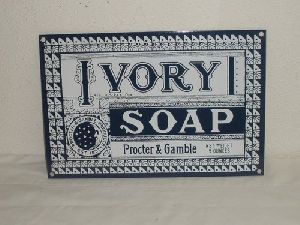

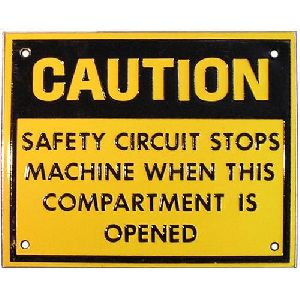

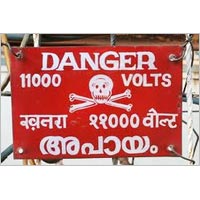

Contact SupplierWe are a reputed Manufacturer, Exporter and Supplier of Enamel Sign Boards. Our vitreous Enamel Sign Boards are made by using the opaque glass and fritting inorganic chemicals like Borex, Quarts, Felspar, Soda Ash, Cobalt oxide, Tit Dioxide in a furnace at a temperature of 1200oC to 1400oC. The molten glass is quenched in water to make it brittle. The Enamel Sign Boards are then pulverized in Ball mills for 24 hours with water as media. These Enamel Sign Boards are quite different to the paints and synthetic enamels that are manufactured by ICI, Asian paints, Burger, Nerolac, and so on.

Attributes