Listing ID #4215054

Company Information

Ask for more detail from the seller

Contact SupplierDescription

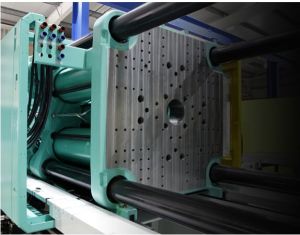

INJECTION UNIT

| Screw Diameter | mm | 27 | 35 |

|---|---|---|---|

| Screw L/D Ratio | 20 : 1 | 18 : 1 | |

| Max.Shot Wieght (PS) | gm's | 64 | 130 |

| Max.Injection Pressure | kg/cm² | 1300 | 1065 |

LOCKING UNIT

| Mould Clamping Force | Tons | 40 | 50 |

|---|---|---|---|

| Mould Clamping Stroke | mm | 200 | 240 |

| Mould Thickness - Min-Max. | mm | 150 | 300 |

| Max.Day Light Opening | mm | 350 | 540 |

| Space Between Tei Bars - H x V | mm | 360 X 310 | 190 X 180 |

| Platen Size - | mm | 250 X 200 | 300 X 300 |

HYDRAULIC EJECTOR

| Ejector Stroke | mm | 40 | 50 |

|---|---|---|---|

| Ejector Force | Tons | 1.7 | 2 |

GENERAL

| Electric Motor | HP | 5 | 7.5 |

|---|---|---|---|

| Heating Capacity | HP | 3.5 | 5 |

| Total Connected Load | HP | 8.5 | 12.5 |

| Tank Capacity | Ltrs | 100 | 150 |

| Machine Weight | Tons | 1 | 1.75 |

| Floor Space ( L x W ) | Mtr | 2.39 X 1.85 | 2.24 X 0.89 |

| Floor Space ( L x W ) | Feet | 7.84 X 6.1 | 7.35 X 2.92 |