Listing ID #5618392

Company Information

Ask for more detail from the seller

Contact SupplierThese Machines are generally used for :

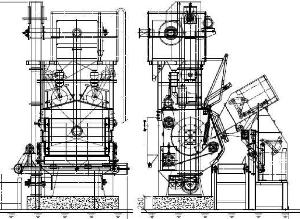

Working Principle of the Plate Cleaning Machine :

These Type of Machines basically consist of under mentioned Parts :

ADL Blastek Industries is an established organization from Jodhpur (Rajasthan) that has been offering a wide range of industrial products and equipment. We serve as the foremost manufacturer, exporter and supplier of the finest Shot Blasting Machine (airless/air operated shot blasting machine), shot peening machine (airless/air operated shot peening machine), Blast Room System (recessed hopper type/ single cross mechanical screw conveyor type/u-shape mechanical screw conveyor type/h-shape mechanical screw conveyor type/full floor screw conveyor type/scrapper type), Paint Spray Booth (semi downdraft/downdraft/end draft/water curtain type), Industrial Dust Collector (fabric/pulse jet/cyclone), Spare Parts (airless/pneumatic machine spare parts), and Baking Oven. We manufacture all these products for various applications to meet the requirements of different sectors i.e., steel, power, construction, railway, casting, foundry & forgings, automobile, aviation, stone-marble, shipyard, agriculture and petrochemical, heavy & general engineering, medical etc. We continuously invest in the amplification of technological & manufacturing process so that we can develop sophisticated and cost-effective techniques for producing machine, which results in high performance, least running cost, low maintenance, high life and reliability.

ADL Blastek Industries is a privately owned and indigenous manufacturing company, started its production operations back in the year 2015 by setting up a unit to manufacture high-quality products at Sangaria Indsutrial Area, which lies in the north-western state of Rajasthan in India. Mr. Vijay Kumar is the COO of the company.

Vision

We share the vision and belief to produce best quality & high-performance equipment with anxiety for safety and environment, by continuous technological development and up-gradation. We aim to maintain dignity and equity in relationships with customers through excellent communication and services.

Mission

To professionally customize & proactively create diverse products to accomplish industry & customer needs.

Quality Policy

We are committed to deliver quality product & services by continuously improving our work process and periodically reviewing effectiveness of our quality management system to meet or exceed customer’s expectation.