Company Information

Ask for more detail from the seller

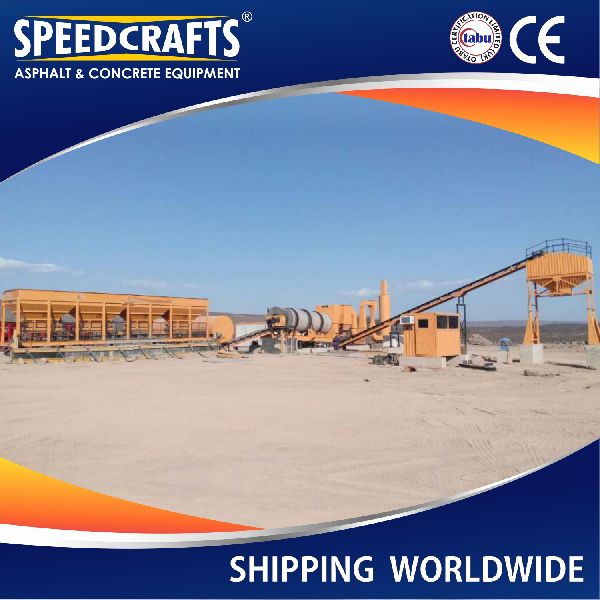

Contact Supplierour asphalt plants built to stringent international and indian standards have found acceptance and acclaim by all users. They are thoroughly inspected and tested for quality and reliability by experienced engineers, faithfully uncompromising on quality. The checks begin with the incoming material and components and end only when the finished product is tested and despatched. We are committed to provide inspired services of the highest achievable standards for absolute satisfaction of our valued customers in terms of sales and service.

features

advantages

dryer drum

the dryer is accurately fabricated to ensure proper heating of aggregates with minimum heat loss. It is supported on steel rollers through steel tyres with idlers and guide rollers and is provided with segmented driving sprocket.

four bin feeder

it is of single chassis construction. At each bin, a radial gate is provided which can be opened in any position to regulate the aggregate flow. Individual endless belts fitted with variable speed motors discharges material onto the gathering conveyor as per the mix design.

controls

a fully automatic control panel with feather touch controls are provided for controlling the quantity and quality of production with operator sitting in air-conditioned comfort.

all systems are completely synchronised with automatic / manual control of burners, load cell, mix temperature, cold feed, mineral, bitumen proportions, etc. Manual control is possible through over-ride system. Adequate safety measures are adopted to avoid overloading, shor t-circuit, etc.

vibratory screem

a single-deck vibratory screen is provided to remove oversize aggregate received from the four bin feeder.

multicyclone exhaust

the dust collection system consists of enclosed multiple cyclones, exhaust fan and chimney.

conveyors

a slinger conveyor is provided which receives aggregate from the four bin feeder and feeds it to the dryer drum.

loadout conveyor fitted with hydraulically operated hopper is provided at the discharge end of the dryer drum which feeds the hot mix material into tippers.

dryer burner

a fully automatic, high pressure, auto jet burner is mounted at one end of the drum.

flight design

the drying and mixing unit of the plant demands complex flight design. Specially designed flights lift and cascade the aggregate to reduce the final moisture content to 0.5% (by weight).

filler unit

fabricated from steel plates, it feeds the required quantity of mineral to the dryer drum.

asphalt (bitumen tank)

tank of 15/20 mt capacity is provided, fabricated from steel plates with 50 mm glasswool insulation, manhole, thermocouples, etc. Bitumen is pumped to the dryer drum through hot oil jacketed pipelines. Tanks are fitted with independent on-off type burners.

fuel tank

one tank of 2500 / 5000 / 10000 ltrs. Capacity is provided with each plant.