Listing ID #3921689

Company Information

Ask for more detail from the seller

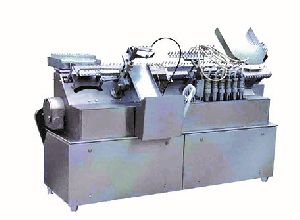

Contact SupplierThe most advanced and high speed vertical ampoule filling and sealing machine with eight head is quite significant as far as the production capacity is concerned. Per minute output is 80 to 280 ampoules with 0.5ml to 10ml filling capacity in single dose. Ampoule Filler And Sealer works well with the varied ampoule sizes ranging from 1ml to 10ml open mouth glass ampoules. Our ampoule filling and sealing machines having CE certifications

Manufacture Precision:-

Precise volume filling, minimum breakage, accurate quality sealing without defects and high reliability are the important functionalities. Heavy duty SS piping for jerk free operations, Stainless steel cladding, epoxy paint and MS anti-rust treatment to plates (base, side and middle) have made the structure sturdy for long run.

Operation:-

Ampoules can be infeed through SS conveyor from a sterilizing tunnel and transfer them to a segment wheel to carry on to a moving rack, which transfers the ampoules in vertical position through the station one by one. The ampoules are discharged to the collection tray after sealing.

Production Capacity can be varied based on the size of ampoules. 290 ampoules can be processed per minute for 1ml size. Similarly if the size of ampoule is 2ML than 270 Ampoules, 3ML 260 Ampoules, 5ML 240 Ampoules, and 10ML 150 Ampoules per Minute output can be achieved.

Actual output can be ± 10 % depending on diameter of ampoules. – Tolerance and diameter ± 0.25mm & height is ± 5mm.

Silent Features