Listing ID #3806154

Company Information

Ask for more detail from the seller

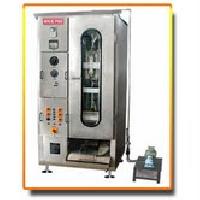

Contact SupplierWe export variety of vertical FFS machines, Milk LDPE Pouch Packing Machine, Automatic Filling and Sealing Machine, Edible Oil Packing Machine, milk pouch filling machine, edible oil pouch packing machine, tomato ketchup pouch packing machine, automatic edible oil pouch packing machine, pharmaceutical powder pouch packing machines, water pouch packing machine, liquid packing machine, pouch packing machine automatic form fill seal machinery, form fill and seal machinery, filling machinery, sealing machinery, honey packing machine, pillow packaging machine etc at industry competitive prices.

Application:Milk, Oil, Lassi, Flavored Drink, Water etc.

Packaging Range: 200-1000 ml

| Features | Advantages | Benefits |

| Option of Single/Two Track | Option of higher speed | Savings on Time/ Space/ Power and Economical |

| Pneumatic Coding Device | To Print M.R,P, Month of Packing, Lot No. etc | Helps In Detecting Manufacturing and Expiry Date |

| Batch Cutting Device | Cuts the Batch at Prefixed length | Ease of secondary packing |

| Precision Sealing | No Laminate and Product wastage | Savings on wastage |

| Photo Registration Control system | Automatic adjustment and correction of Pouch sealing | Savings on wastage |

| Operator Friendly/Low Maintenance | Easy to Operate / Less Servicing Machine Required | High Run Time /Increased Productivity |

| Machine is PLC controlled | Machine is centrally controlled | System runs in Synchronization |

| Food Grade Stainless steel Contact parts | No rusting | Long Life, Hygienic Packing |

| Machine is Elegant, Castor Mounted | Looks appealing, Easy to Install and move | Less labor is required for displacement |

| Machine is equipped with PID | Displays and controls Sealer's Temperature | Optimum Temperature for Sealing Better Sealing |