Company Information

Ask for more detail from the seller

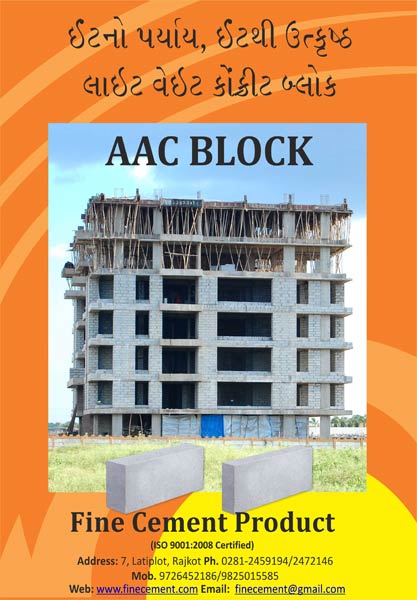

Contact SupplierWe are engaged in offering Ecolite - Autoclaved Aerated Concrete Blocks, which are a perfect alternate for bricks in wall masonry. Our Ecolite AAC Blocks are manufactured as per IS 2185 III quality certifications. Our wide range of Ecolite AAC Blocks offers a solution that precisely addresses the specific needs of the clients. Ecolite AAC Blocks make an excellent building material because of their outstanding thermal properties, superior fire resistance and excellent acoustical absorbing abilities. The Ecolite AAC Blocks, we offer, are light weight, easy to work with, versatile in nature and extremely durable. Ecolite AAC Blocks consist of Quartz (Silica and PFA) which is the largest of the dry materials involved. The silica along with the cement and lime mixture reacts with the aluminum to form the millions of tiny cells that give Ecolite AAC Blocks their unique properties.

Ecolite AAC Blocks Applications

Features

| Particulars | Units | Sizes |

|---|---|---|

| Size | mm | 625 X 240 X thickness |

| Thickness | mm | 50,75,100,125,150,200,230 - 300 |

| Compressive Strength | N/m2 | 3.5 - 4.0 ( IS 2185) |

| Normal Dry Density | Kg/m3 | 550 - 650 |

| Sound Absorption | dB | Upto 42 |

| Thermal Conductivity 'K' | w/m2k | 0.16 |

| Fire Resistance | Hrs. | 4* |

| Thermal Resistance | K-m2/W | 0.46 |

| Heat Transmission Coefficient 'u' | w/m2k | 2.17 |

| Drying Shrinkage | % | 0.04% (of the length of block) |

| Note : For 200mm thick wall | ||