Company Information

Ask for more detail from the seller

Contact SupplierCeramic CPU’s, plastic CPU’s and Motherboards are put aside and separated from each other.

4.1 The Mechanical Process:

PCB’s are broken into the size of 1 - 1,5 mm, then the precious metal including parts are separated from the aluminum, plastic parts and ferrous metals. Acoording to the raw material the IC component system is used for enrichment.

4.2 Copper Enrichment Process:

After the physical preparation, Non-ferrous metals fed into the Special Smelting Furnace. The metals as Lead and Tin dissolves into the furnace and cathes in the filters for casting into anodes.

4.3 The Electrolysis Process:

After casting anodes, the anodes placed into electrolysis tanks. With these process copper recovered as cathodic solid copper. The remaining precious metal containing clay will be dehydrated with the Filtre Press system.

4.4 The Chemical Process:

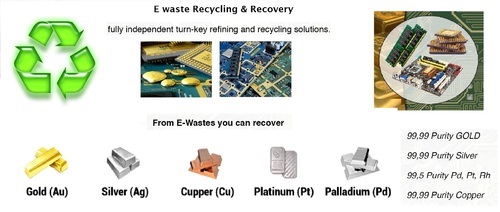

After washing the residue, it is fed into the E-Waste Recycling Machine. Gold, Silver, Platinum and Palladium are recovered using the E-Waste Recycling Machine. If the recovery is required from Gold plated pins, a special Electro - Chemical Recovery System is used.

4.5 The Neutralisation Process:

All waste water is transfered into the Neutralisation System. The remaining metal inside the waste water is recovered, and the water is neutralised to dischargeable standarts .

4.6 The Analysis Process:

After and during all process, the products are being analysed by the fire analysis laboratory. The Induction Melting Furnace and various analysis equipments collected in one set are used for checking the compositions of products.