Listing ID #4007912

Company Information

Ask for more detail from the seller

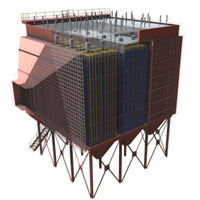

Contact SupplierThe casing of Rotary Polygon Screen will be fabricated from 3 mm thick m.s. sheets suitably reinforced with rolled steel sections. The bottom part of the casing will be rectangular in the shape while the top part will be pentagonal or hexagonal in shape and bolted to the bottom part. Removable panels/doors will be provided in the top part of the casing for inspection purpose. A feeding/receiving chute will be provided at one end of the top part to receive sand from conveyor, elevator or similar feeding device. Provision will be made in the top part of the casing in the form of circular opening for connection to dust extraction system.

The main driving shaft of mild steel will be carried at each end in externally lubricated self aligning ball bearing blocks. Keyed to the shaft will be m.s. or cast iron hexagonal hubs fixed to which will be m.s. radial arms on which will be bolted the frame carrying replaceable wire mesh screen.

Product ranges from capacity of 10 tons/hr to 80tons/hr.

For removal of large pieces of scrap and hard lumps of sand etc. which cannot pass through the wire mesh screen and which travel right through to the end of the screen, suitable reject opening will be provided.

Drive will consist of motor with gearbox . Necessary sheet metal steel guards will be provided over the coupling.