Listing ID #6812617

Company Information

Ask for more detail from the seller

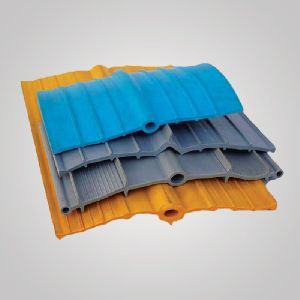

Contact SupplierSelection of appropriate PVC water stopper Ribbed Type – It has a multi-purpose water stopper design to be used for the expected differential settlement of poured concrete and a firm concrete grip desired. Dumbbell Type – With greater variation in temperature, expansion and contraction of joints happen. Dumbbell type water stoppers are the suggested ones for these cases. Kicker (Surface Type) – Where the embedded types cannot be used owing to interference of steel reinforcement, these are placed externally. Installation procedure: During installation, using small wires, the water stoppers are tied to the steel framework through the eyelets. Also, certain metal clamps are used to grip the water stop seal and keep it in proper position. Initially, half of the water stopper is places in the concrete. It leaves the other half extended. Then, the other half is embedded that leaves the centre bulb free for expansion and contraction movements. Applications Of PVC Water Stoppers Public Utilities: For bridges, road embankments, tunnels, water tanks, water filtration systems, swimming pools, sewage plants, clarifiers, dams, canals, reservoirs, aqueducts and irrigation projects cooling towers. Buildings: For basements, foundations slabs, masonry joints, retaining walls, terraces, overhead & underground water tanks and Industries: For fertilizer steel, chemical plants, waste treatment plants, atomic reactors, thermal & hydro power stations and shipyard & docks. Precautions to take while water stopper installation They are vulnerable to damage during the construction process The concrete compaction around the water stopper should be taken care of. If not, it can dislocate and lead to a risk of honeycomb formation. This might result in leakage through concrete instead of the joint. Methods for joining PVC water stoppers with heater blade Water stoppers can be joined on the site using a simple electrical heater blade. Water bars having the same width and design should be sharply levelled with a knife at the Turn on the Electric Heater Blade. Wait till it becomes hot Place the water stopper on both sides of heater blade. Press it until it melts but without burning Remove the heater blade upward Join the molten ends quickly. Hold them together firmly for approximately 20 to 30 seconds. PVC Water Stopper with Center Bulb 150 (6") x4mm 150 (6") x5mm 150 (6") x6mm. 150 (6" ) x8mm 150 {6") x10mm 200 (8" x 8mm 200 )8") x10mm 240 x 8mm 240x10mm. 250 (10") x8mm 250 (10") x10mm 250(10" x12mm 300 (12") x6mm 300 (12") 8mm 300 (12") 10mm 300 (12" ) 12mm 300(12") 15mm A PVC water stopper is a device used in construction to prevent water from penetrating through joints or gaps in concrete structures, such as basements, swimming pools, water tanks, and underground structures. It is commonly used to provide a watertight seal and protect the structure from water damage. PVC water stoppers are typically made from high-quality polyvinyl chloride (PVC) material, which is durable, flexible, and resistant to water and chemicals. They come in various shapes and sizes to accommodate different types of joints and applications. The most common shapes include "dumbbell" or "center bulb" profiles, which provide effective sealing against water ingress. Installation of PVC water stoppers involves embedding them in the concrete joints before pouring the concrete. The water stopper is placed in the joint, and concrete is poured around it, ensuring a tight seal. The flexibility of the PVC allows it to accommodate slight movements or vibrations without compromising the water seal. PVC water stoppers are preferred over traditional alternatives like rubber or metal due to their excellent chemical resistance, cost-effectiveness, ease of installation, and long-term durability. They are also available in different grades to meet specific project requirements, such as resistance to hydrostatic pressure or chemical