Listing ID #7484592

Company Information

Ask for more detail from the seller

Contact SupplierAuger fillers use load cells and balances to control the fill level. The system can operate in feedforward, bulk, or setpoint modes. In feedforward mode, the auger runs at a high speed for the most of the fill before slowing down to dribble pace for the last bit of the fill.

A dry powder filling line is made up of a variety of devices that may control the fill weight. In the designs of these devices, load cells and balances are frequently used. These devices may be able to control weight in one of three ways, depending on their configuration: setpoint, bulk, or feedforward. In setpoint mode, the auger fills at a quick rate for the majority of the time before dribbling slowly.

Either an automatic or semi-automatic filling line is available. For lighter weights, semi-automatic filling lines are appropriate. Two weigh cells are required on a filling line in order to achieve zero error in volumetric filling. While the other measures filled bottles, the first weighs empty bottles. The fill weight is the difference between the tare weight and the gross weight.

There are two categories of bulk dry powder filling lines: automatic and semi-automatic. The automatic kind fills dry powder bottles using a single head auger. Semi-automatic fillers don’t need someone to work by hand. They may be set up in one step or two steps.

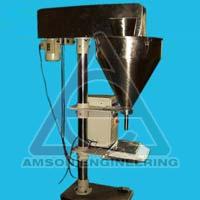

An auger that turns a hopper is a component of semi-automatic auger fillers. This machine is simple to maintain and is built to provide extremely accurate fills. The hopper and auger are both constructed of stainless steel. Sensors also aid in controlling the flow of powder into packing.

Double head dry powder filling Machine are incredibly adaptable and can accommodate a wide variety of powders. They have two distinct filing heads that cooperate to fill each bottle evenly and consistently, as opposed to a filler with a single head. They can handle numerous fills each minute depending on the amount of powder and might be a terrific, cost-effective solution for your company.

Any size of production plant can instal single- or double-head filling lines. They are appropriate for businesses in the pharmaceutical, food, biotech, and agricultural sectors. Due to its small size and construction in corrosion-resistant stainless steel, they require little maintenance and have a long service life.

High levels of automation are seen in robotic filling and capping equipment for dry powder filling lines. They can also be created to fulfil particular customer requirements. They are perfect for usage in pharmaceutical, nutraceutical, cosmetic, and food goods and can be used with a variety of closure styles.

Pharmaceutical powders are an essential part of many drugs, such as antibiotics and painkillers. Filling medications in liquid form is challenging enough, but when utilising powders—which are significantly more abrasive—the difficulties rise. The amount of dust produced by the finely ground active substances can be very dangerous for machine workers.

A filling line is made up of several different machines. While some are operated manually, others are entirely automated. Some even have an integrated weigher to provide the most precise filling. The most crucial choice, regardless of the filling line type, will be which tools and drives are ideal for your individual requirements. The amount of powder in a certain container must be precisely measured before filling.

To create pharmaceutical dosage forms that are fully compliant with new requirements, a dry powder filling process can be constructed. Straight-line layouts are possible for these devices, which reduce cross-contamination and preserve aseptic standards.

Dry powder filling Machine comes in many distinct varieties. The Automatic Injectable Powder Filling Machine is one of them; it’s a small model made for filling vials with dry powder.

We as a VS Technofirm Engineering are a renowned manufacturer and supplier of high-quality industrial machinery. Our available range of products consists of Automatic Vial Labelling Machine, Automatic Rotary Labelling Machine, Rotary Sticker Labeling Machine, Automatic Self Adhesive Labelling Machine, Vertical Self Adhesive Labeling Machine, and Round Bottle Labelling Machine, etc. Our machines are best known for their quality. After wide success in the packaging and pharmaceutical engineering sector, we have launched a new unit for PFS, IV, and all other aseptic production lines and products under the name HPM Machines, since 2020.

At HPM Machines, we specialize in manufacturing and supplying an extensive range of production lines, including Injectable Liquid Vial Filling Line, Dry Powder Filling Machine, and Automatic IV Fluid Bottle Packing Line since 2017. Our labeling machines, such as the Syringe Plunger Rod Screwing and Labeling Machine and the Automatic Vertical Vial Sticker Labeling Machine, are recognized for their precision and reliability. Additionally, we offer a variety of washing machines like the Gripper Type Automatic Rotary Ampoule Washing Machine and the Automatic Linear Bottle Washing Machine.

Our filling machines include the Automatic Vial Filling and Bunging Machine, Syrup Filling Machine, Eye Drop Filling Machine, Semi-Automatic PFS Filling Machine, and more. We also provide seal machines, pharmaceutical sterilizing tunnels, automatic air jet cleaning machines, visual inspection machines, packing conveyor belts, stainless steel swing conveyors, and stainless steel turntable machines.

Our company is equipped with an expansive infrastructure and advanced technology, ensuring the production of durable and efficient machinery. Our team works in close coordination to meet various requirements within approved time frames. Our infrastructure supports the streamlined execution of business operations and houses advanced machines and tools, enabling us to meet bulk orders efficiently. All products are stored safely in our spacious warehousing unit.

We pursue excellence from initial consultation to superior warranties and follow-through, providing reliable and continuous 24/7 support, machinery installation and upgrades, and emergency solutions. Under the leadership of our founder, Mr. Satish Kumar, we are committed to maintaining high standards and fulfilling virtually any client needs.