Listing ID #4023240

Company Information

Ask for more detail from the seller

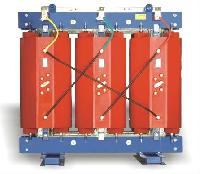

Contact SupplierIn cast-resin dry-type transformers, the complete encapsulation of primary and secondary winding in epoxy resin prevents penetration of moisture into windings. The cast resin offers very good protection against adverse ambient conditions. These transformers can work without disruption of service at 100% humidity.

Due to the high grade insulation material, coils are non hygroscopes & the transformer can be switched on directly without pre-drying even after a long period of service interruption.

Contrary to the conventional dry type transformers the cast coil transformers are better in respect of impulse voltage withstand strength.

Higher dynamic short circuit withstands strength as compared to oil immersed and conventional dry type transformers because of fibre glass reinforced epoxy encapsulation. No partial discharges can occur during operation. The insulation material used is glass fibre reinforced with epoxy resin of class 'F' which can withstand wide temperature variation. Due to high quality insulation material the transformer is practically non-inflammable by an electrical arc, special fire protection measures are not required.

Due to encapsulation of coils with cast resin the coils dimensions are stable & no coil tightening is required to maintain the short circuit strength. Also no check of oil level and electrical insulation/oil is required. This leads to saving in cost on account of maintenance.

As cast resin transformers are solidly cast, problem associated with oil filled transformers like oil leakage and pilferage of oil is completely avoided.

These transformers are generally smaller in dimensions and lesser in weights. The construction and installation cost for the sub-station can be reduced by adopting dry type transformers.

Without fire or danger of explosion, it is possible to place the transformers near to the load centre. Also, these transformers do not need construction of special fibre brick walls or oil pits, which reduces the overall civil works. Additionally, since LT cables are not required, thers is also saving in cost on account of expensive cable laying works.

Since no oil is used in these transformers, there are no chances of contamination of ground water due to oil leakage.