Listing ID #3943691

Company Information

Ask for more detail from the seller

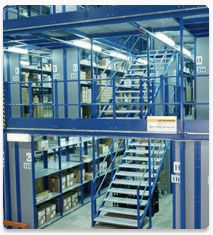

Contact SupplierDrive –in Racks allow a lift truck to enter the rack from one side to pick up or pull out pallets. This is done because pallets can slide backwards on a continuous rail. Forklifts drive into the rack to access pallets two or more deep.

Drive- in rack can be configured to store loads three, four or more deep, creating extremely dense storage. A drive-in system, that stores pallets four high and five deep, for example, can hold 20 pallets storage bay, place a load in the desired position and the back out.

To allow lift trucks in to the bays, drive in systems are designed without traditional beams placed across the bays. Instead, pallets rest on rails that run along the insides of the bays, perpendicular to the aisles. Pallets in a drive-in racking system are stored on a First-in / Last-out basis (FILO). Each bay is typically dedicated to a single product, so drive-in rack is best used in warehouse storing large quantities of the same product.

USAGES

Drive - In racking is used where high-density storage is required. It is frequently used in facilities with a low number of product lines. Pallets are stored in a block system with two blocks generally served by one operating aisle. The trucks drive into the racking to load or retrieve pallets, which are stored on cantilevered rails running throughout the system. The first pallet in is the last one out unless a Drive-Through system is used whereby pallets can be loaded or retrieved from either side. Forklift trucks drive into lanes on racking specially built to provide support to the pallet along the pallet sides. Stacking often to 10 metres high and 4 or 5 but occasionally even 10 pallet positions deep. This system can provide a very dense storage capacity, often low in access and rotation of products. As the truck enters the racking, special precautions apply to ensure the compatibility of design between the truck, pallet, load and the racking. Flat floors are advantageous.Usually the rack design incorporates a stability structure at the rear of the rack and therefore drive in indicates single access from one side. Drive through requires this same stability to be provided by a variation in design.