Company Information

Ask for more detail from the seller

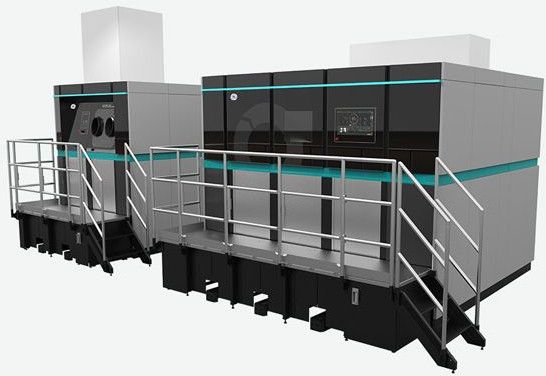

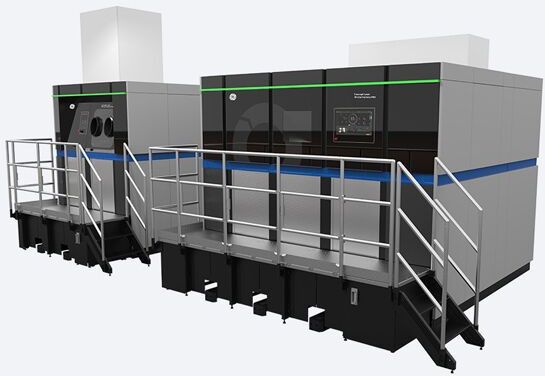

Contact SupplierThe metal-based additive manufacturing technology, particularly Direct Metal Laser Sintering has been the preferred choice for metal additive manufacturing machines for nearly many years, establishing itself as the standard in metal 3D printing. DMLS technology enables the production of metal parts that achieve uniform quality and characteristics comparable to those obtained through traditional casting or forging processes. Our industrial 3D printing systems are designed for seamless integration into existing production environments, offering a variety of build space sizes, laser power ratings, and scalability options. Whether you require compact systems for the manufacture of intricate metal components or mid-sized solutions for a diverse range of compatible materials, our offerings cater to all industrial needs, delivering precision and efficiency in metal additive manufacturing.

Freedom of Design 3D printing unleashes completely new design opportunities for application engineers. The possibility to manufacture complex parts with almost no limits enables completely new possibilities.

Complex Geometries

Many applications require complex geometries to fulfill their purpose. However, traditional manufacturing oftentimes sets boundaries that are completely redefined through additive manufacturing.

· Maximized Productivity

Scale your productivity through our portfolio of metal solutions that adapt to your needs. From material and process management to our digital solutions - maximizing productivity and system utilization is your key to success

· On-Demand & Customized Manufacturing

Many of our customers rely on additive manufacturing for on-demand production to avoid over production and tooling costs. Spare parts are a typical examples but also customization of parts is a key benefit of additive manufacturing.

Robust system design and powerful fiber laser deliver reliable high performance, day in and day out.

Reproducible Part Quality

The exceptionally high beam quality of the laser spot and the excellent detail resolution are ideal for producing highly complex components with homogeneous properties.

Broad Portfolio of Materials

With the most extensive range of validated materials and processes available on the market, all customer needs are covered.

Comprehensive Quality Management

The comprehensive monitoring suite enables quality assurance of all production- and quality-relevant data in real time.

Key Benefit Of Additive Manufacturing.

Highly Productive

1000-watt laser power increases productivity with higher build rates and thicker layers. Ideal for serial manufacturing of large metal parts.

Easy to Use

Coating both sides with powder material reduces production downtime. A circulating air filtering system with automatic cleaning means fewer filter changes and longer service life.

Broad Portfolio of Materials

A comprehensive collection of materials is available, from light metals to stainless steel, tool steels and super alloys.

Technical Data

Build Volume

400 x 400 x 400 mm (15.7 x 15.7 x 15.7 in)

Laser Type

Yb-fiber laser; 1 x 1000 W

Presicion Optics

1 F-theta-lens(es); 1 High-speed scanner(s)

Scan Speed

up to 7.0 m/s (23.0 ft/s)

Focus Diameter

approx. 90 µm (0.00354 in)

Power Supply

1 x 50 A

Power Consumption

max. 50.2 kW / typical 16.2 kW

Compressed Air Supply

7 Bar; 20 m³/h (102 psi; 706 ft³/h)

Machine Dimensions

4181 x 1613 x 2355 mm (164.6 x 63.5 x 92.7 in)